Electric Forklift Assembly Line

Electric forklift production follows three pillars: modular pre-assembly, online control of torque, sealing and electronics, and full-load bench validation. A typical line runs 28 U-shaped stations at 5-6 min takt, fed by three sub-lines for mast, battery and axle, uses AGV shuttles, servo presses and RFID racks, and stores every torque and test value in MES for ten-year traceability. Vacuum oil fill, force-controlled roller pre-load and EMC-compliant debug guarantee performance, while automatic welding, digital twins and one-piece flow cut change-over to under eight minutes and push first-pass yield above 98 %.

Below is a systematic summary of “structure → assembly technology → assembly line” for electric forklifts, drawn from publicly available industry data and the line practices of certain leading OEMs (hereafter referred to as Brand A, Brand B, Brand C and Brand D).

Overall Structure (Modular Breakdown)

- Frame module

– Skid-steer, weldment frame made of ≥5 mm high-strength plate; laser cut + robotic MAG welding; torsional rigidity ≥18 kN·m/°.

– Battery compartment: centrally sunk layout for low C-of-G and lateral stability; 15 mm peripheral groove for quick-swap Li-ion or lead-acid packs. - Mast system

– 2- or 3-stage full-free, wide-view mast; main rollers use maintenance-free composite bushings; lift cylinders rear-mounted or dual-side mounted to reduce load centre distance. - Drive module

– Single or dual AC PM motor + planetary gearbox in one unit; electronic parking; motor peak efficiency ≥92 %; IP54 protection. - Control module

– Vector inverter + MOS/IGBT rectifier; pre-charge contactor; 0-15 km/h stepless; whole-machine EMC meets CISPR 25 Class 3. - Hydraulic system

– Stand-alone 3 kW gear pump + load-sensing multi-way valve; lift speed 280-320 mm/s; tilt cylinder with lowering cushion valve to prevent shock. - Auxiliary module

– Overhead guard, dash panel, counterweight (cast-iron or steel + concrete composite); meets GB/T 5143 4.5 t drop test.

Key Assembly Points (Process Sequence)

- Parts IQC & pre-cleaning

– Critical holes 100 % laser re-checked; Ra≤12.5 µm; shafts and bearings ultrasonic cleaned and coated with DFP rust preventive. - Frame pre-assembly (inverted line)

– U-shaped pre-assembly island + KBK hoist; steer axle, tilt cylinder, tank and hoses fitted in sequence; DC electric nut-runner, critical torque 120 N·m ±3 %, data auto-upload to MES.

– Axle-to-frame dowel fit H7/g6; pins chilled to 5 °C before insertion to obtain 0.01-0.03 mm interference. - Battery & motor marriage

– Li-ion modules auto-welded off-line, EOL test (voltage diff. ≤20 mV, IR ≤0.5 mΩ) before insertion; battery box fixed to frame with eight bolts and 1242 sealant for corrosion protection.

– Drive unit two-step: ① servo press pushes motor-gearbox into axle housing; ② AGV lifts and docks the whole unit, two Φ12 taper pins driven; concentricity ≤0.05 mm. - Mast/fork carriage sub-line

– Roller pre-load on-line check: force-displacement sensor, 450-500 N at 0.2 mm deflection; QR code auto-engraved for traceability. - Hydraulic quick-connect & vacuum fill

– German quick-couplers, pull-off force ≥500 N; –85 kPa vacuum, 30 s leak-free hold; ISO 46 anti-wear oil, NAS 8 cleanliness. - Harness & control calibration

– 100 % continuity + 500 V DC insulation ≥20 MΩ; controller flashed with unified CCU software; “twist-grip – travel – brake” 3-point calibration (linearity ±2 %). - 100 % dynamic bench test

– 1.25×rated load, 200 consecutive lifts, oil temp ≤80 °C; 15 % ramp, full-load parking 5 min no slip; EMC chamber 30-1000 MHz radiated disturbance ≤40 dBμV/m.

Line Layout & Automation Level (Brand A / B / C Cases)

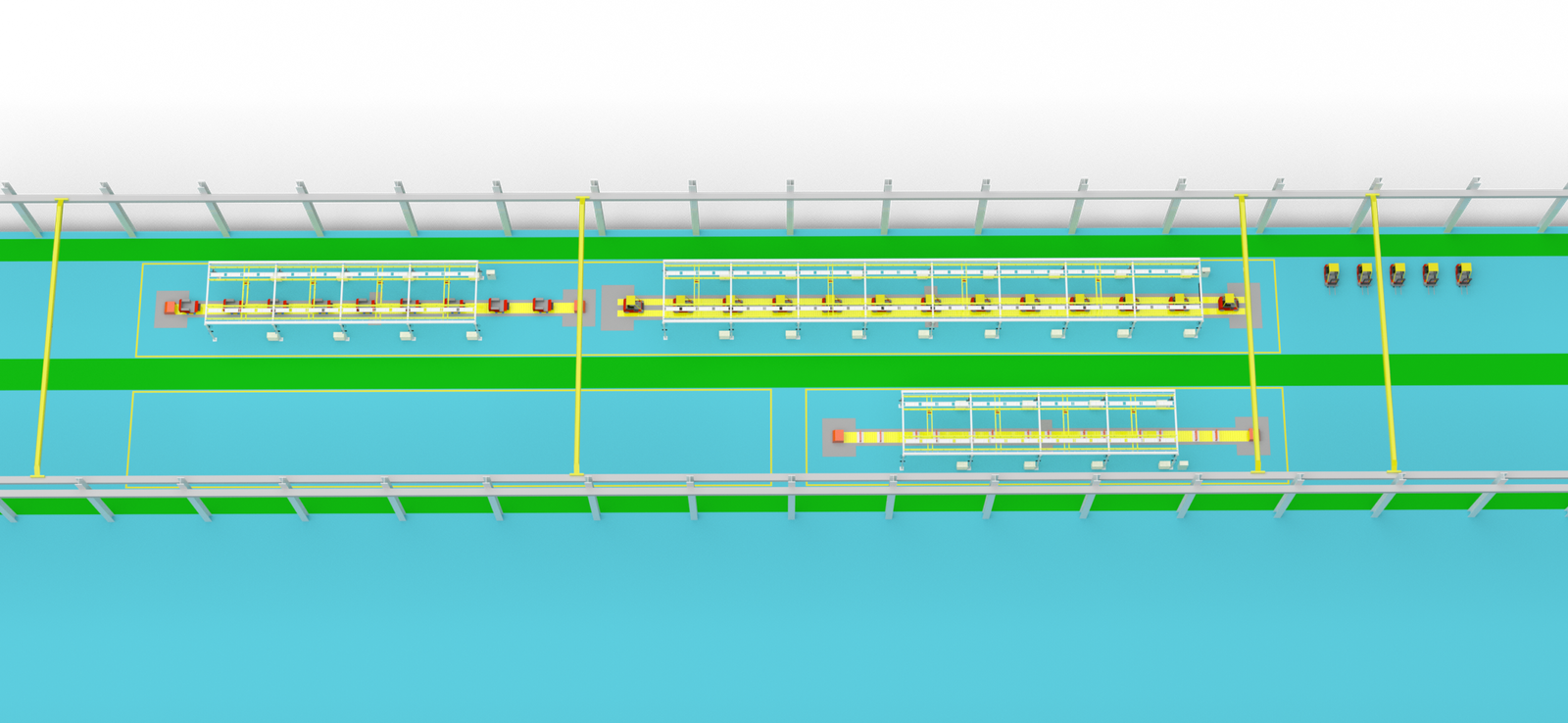

- Line configuration

– 1 main line + 3 sub-lines (mast, battery, rear axle); takt 5-6 min/unit; capacity 30 k units/year; 28 main stations; AGV synchronous shuttle; 0.7 m liftable deck. - Key equipment

– 6-axis robots ×2 (frame welding & seat bracket), repeatability ±0.05 mm;

– 20 kN servo press with force-displacement curve, auto reject NG parts;

– Smart rack: RFID pick-to-light, 99.8 % error-proof;

– MES linked to ERP/WMS, one-file-per-truck; critical torque & test data kept 10 years for traceability. - Quality gates

– T0 IQC; T1 post-weld; T2 pre-assembly; T3 main assembly; T4 after debug; T5 finish/final QC. Target first-pass yield ≥98 %, rework rate ≤0.5 %. - Green & Safety

– Welding fume central filtration <4 mg/m³; oil vacuum collected, waste centralized; 48 V safe lighting; 1 s emergency stop; AGV zone infrared + safety bumper dual protection.

Benchmarking Differences Among OEMs

- Brand A: flexible skid + group technology, 1-3 t three wheelbases on same line, change-over ≤8 min.

- Brand B: mast robot laser-tracking, weld penetration ≥1.2 mm, UT first-pass 99.5 %; digital twin predicts OEE in real time.

- Brand C: in-house Li-ion, battery-box & frame integrated, saves 6 % weight; “active line” with servo tightening + on-line SOC test, 5-year/10 000 h battery warranty.

- Brand D: premium models use one-piece flow, 100 % auto-check at key stations; 24 h reliability enhancement (1 500 cycles at 2×rated load) after roll-off.

Take-away

The core of electric-forklift assembly is “modular pre-assembly + on-line monitoring of critical torque/sealing/e-control + full-performance bench re-test”. Using the proven practices of Brand A, B, C and D as a baseline, a new line can adopt “5 min takt, 28 stations, U-shaped layout, MES traceability” and then fine-tune for volume and flexibility to reach first-class industry level.