How to customize a suitable assembly line

Customizing an assembly line requires fully considering product characteristics, production scale, cost constraints and other factors, with obvious differences between home appliances and automobiles. Home appliance assembly lines need to balance automation and cost according to product size and batch size, with flexible adjustment space for iteration. Automobile assembly lines focus on high precision and safety, adopting automated equipment for key processes and modular design for mixed production. Both should integrate intelligent systems and conduct trial operation optimization to improve efficiency and quality, and the investment payback period varies according to product types.

How to Customize a Suitable Assembly Line: With Reference to Home Appliances and Automobiles

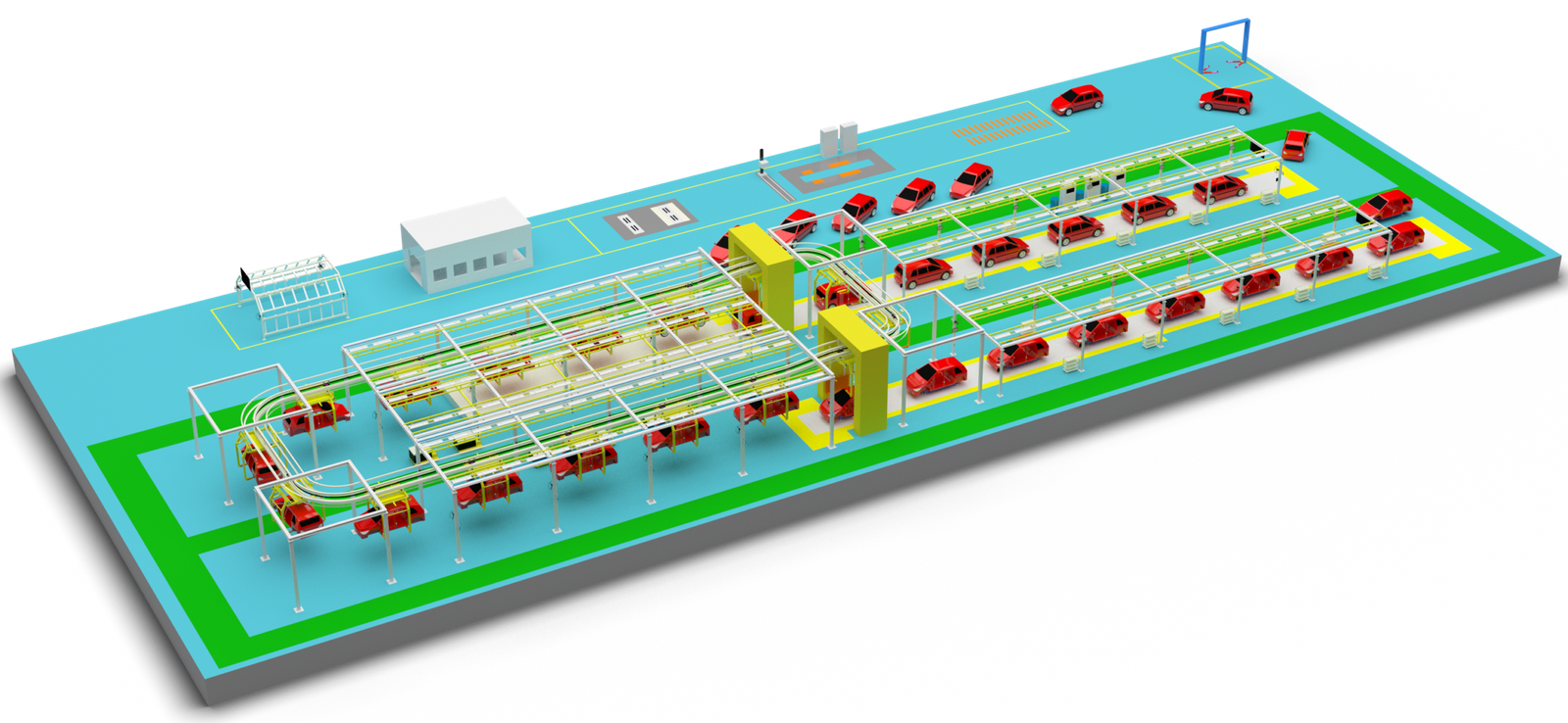

Customizing a suitable assembly line requires integrating core factors such as product characteristics, production scale, and cost budget. Due to significant differences in structural complexity and production batches between home appliances and automobiles, their customization logics have distinct focuses. Below is a full-process customization plan from preliminary planning to implementation, detailed in conjunction with the characteristics of the two product categories.

I. Preliminary Core Research and Demand Analysis

This is the foundation of assembly line customization, requiring clear definition of core production goals and constraints.

- Product Characteristic Disassembly

- Home Appliances: Disassemble according to product category differences, such as refrigerators, washing machines, and air conditioners. Focus on modularity (e.g., compressor, cabinet, door body modules of refrigerators), product size and weight (a single refrigerator weighs 50-100kg, while small home appliances only 1-5kg), and assembly precision requirements (air conditioning pipeline connections need to be sealed to prevent leakage with an error of less than 0.1mm). At the same time, consider the product iteration speed—small home appliances have a short update cycle, so the assembly line must reserve flexible adjustment space.

- Automobiles: Disassemble according to vehicle types (sedans, SUVs, new energy vehicles). Focus on body structure (welding precision error less than 0.5mm), number of parts (a single automobile has over 10,000 parts), and differences in power systems (engine assembly for fuel vehicles, battery pack installation for new energy vehicles). In addition, automobiles have extremely high safety requirements, and key processes (such as brake system and airbag assembly) must meet strict quality standards.

- Production Scale and Capacity Planning

- Home Appliances: Develop plans based on batches. Small home appliances (such as rice cookers) can achieve a daily capacity of 10,000-20,000 units, suitable for high-speed automated assembly lines; large home appliances (such as refrigerators) usually have a daily capacity of 500-2,000 units, requiring a balance between automation and manual operation to reduce equipment investment costs. At the same time, consider capacity fluctuations in peak and off-peak seasons and reserve capacity flexibility.

- Automobiles: Automobile manufacturers typically have a daily capacity of 500-1,000 vehicles, belonging to large-scale standardized production, requiring the construction of a full-process automated assembly line; while auto parts (such as seats and dashboards) supporting factories need to flexibly adjust according to orders from automobile manufacturers, suitable for reconfigurable modular assembly lines.

- Cost and Resource Constraints

- Home Appliances: Small home appliances have limited profit margins, so the assembly line cost should be controlled within 30% of the total investment, prioritizing cost-effective semi-automatic equipment; large home appliances can appropriately increase automation investment to reduce long-term labor costs.

- Automobiles: The investment scale of vehicle assembly lines is large (a single vehicle line can cost hundreds of millions of yuan), requiring a balance between equipment costs and production efficiency. Key processes (welding, painting) use high-automation equipment, while auxiliary processes (interior assembly) combine manual operations.

II. Selection of Core Assembly Line Types

Choose the appropriate assembly line type based on product and capacity requirements. The mainstream choices for home appliances and automobiles are as follows:

| Assembly Line Type | Core Characteristics | Application Scenarios for Home Appliances | Application Scenarios for Automobiles |

|---|---|---|---|

| Belt Conveyor Line | Low cost, stable operation, suitable for light and small products | Shell assembly and parts assembly of small home appliances (rice cookers, hair dryers) | Pretreatment processes of auto parts (such as wire harnesses, small plastic parts) |

| Roller Conveyor Line | Strong load-bearing capacity (single roller load 50-200kg), enabling product steering and lifting | Cabinet transportation and whole-machine testing of large home appliances (refrigerators, washing machines) | Auto body transportation and engine assembly transfer |

| Overhead Conveyor Line | Utilizes overhead space, saves ground area, suitable for large products | Pipeline connection and shell assembly of air conditioner outdoor units | Auto body painting and installation of interior parts (seats, dashboards) |

| Automated Flexible Assembly Line | Can adapt to multi-variety production through program switching, high automation level | Core component assembly of high-end large home appliances (such as smart refrigerators) and mixed production of multiple models | Mixed production of new energy vehicles and fuel vehicles, assembly of key parts (battery packs, motors) |

| Manual Assembly Line | High flexibility, suitable for complex processes or small-batch production | Assembly of customized home appliances (such as built-in kitchen appliances) and rework of after-sales maintenance parts | Small-batch production of modified vehicles and special-purpose vehicles |

III. Key Processes and Equipment Configuration

Configure core equipment according to the product assembly process, balancing efficiency and quality.

- Key Configuration of Home Appliance Assembly Lines

- Front-end Parts Pretreatment: Set up a parts sorting area, use AGV robots to transport parts from the warehouse to the assembly line, and equip lifting equipment (electric hoists, manipulators) for heavy parts such as compressors and motors of large home appliances.

- Core Assembly Processes: Use automated manipulators for screw tightening and part fitting in small home appliances; equip special equipment (such as automatic foaming machines, high-frequency welding machines) for processes like cabinet foaming and pipeline welding of large home appliances. Semi-automatic positioning fixtures are used for assembling door bodies and cabinets to ensure assembly precision.

- Testing and Packaging: Configure special testing equipment, such as air tightness detectors for air conditioners and refrigeration performance testers for refrigerators; use automatic packaging machines and labeling machines in the packaging link to improve efficiency.

- Key Configuration of Automobile Assembly Lines

- Body Manufacturing Link: Adopt robot welding production lines (equipped with 20-50 welding robots per line) to achieve precise body welding; use automated painting robots in the painting link to ensure uniform paint finish and compliance with environmental protection standards.

- Final Assembly Link: Set up chassis assembly lines, interior assembly lines, and powertrain assembly lines. High-precision positioning equipment is used for the combination of chassis and body; special lifting equipment and insulation testing instruments are equipped for battery pack assembly of new energy vehicles to ensure safety.

- Testing and Commissioning: Configure vehicle testing lines, including four-wheel alignment machines, lighting detectors, brake performance testers, and battery performance testing equipment for new energy vehicles. All testing data is uploaded to the system in real time to achieve full-process traceability.

IV. Flexible and Intelligent Design

To adapt to product iteration and capacity fluctuations, the assembly line must have flexible adjustment capabilities, while integrating intelligent technologies to improve management efficiency.

- Flexible Design

- Home Appliances: Small home appliance assembly lines use adjustable fixtures, which can switch between different product models within 10-15 minutes; large home appliance assembly lines reserve equipment expansion interfaces, allowing quick addition or replacement of special equipment when new models are launched.

- Automobiles: Adopt modular assembly units, each of which can independently complete specific processes. When vehicle models are updated, only the equipment and programs of the corresponding modules need to be adjusted; at the same time, adopt mixed production mode, where one assembly line can produce 3-5 different vehicle models. RFID technology is used to identify product models and automatically call the corresponding assembly programs.

- Intelligent Upgrade

- Home Appliances: Introduce a Manufacturing Execution System (MES) to monitor production progress, equipment operating status, and product quality data in real time; equip key equipment with sensors to realize fault early warning and remote maintenance; optimize assembly processes through big data analysis to reduce defect rates.

- Automobiles: Build an industrial internet platform to integrate production, logistics, quality and other data to achieve full-process intelligent management; adopt digital twin technology to simulate the operation status of the assembly line and optimize layout and processes in advance; use machine vision inspection in key processes to replace manual quality inspection, improving inspection precision and efficiency.

V. Implementation and Optimization Adjustment

- Layout Planning: Reasonably layout according to the process flow. Home appliance assembly lines follow the linear process of “parts sorting-core assembly-testing-packaging” to reduce material transportation distance; automobile assembly lines adopt U-shaped or circular layouts to realize continuous transportation of bodies from welding to final assembly, improving space utilization.

- Personnel Training: Operators of home appliance assembly lines need to master basic equipment operation and simple troubleshooting, and those engaged in key processes (such as welding and testing) must hold certificates; robot operators and quality inspectors of automobile assembly lines need to receive professional training to be familiar with the operation and data analysis of intelligent equipment.

- Trial Operation and Optimization: After the assembly line is completed, conduct a 1-3 month trial operation to collect information such as production data, equipment failures, and product quality. Optimize process cycles and equipment parameters in a targeted manner; adjust personnel allocation and production processes based on trial operation results to ensure that capacity and quality meet standards.

VI. Cost and Benefit Evaluation

After customization, evaluate from the aspects of short-term investment and long-term benefits:

- Home Appliances: The investment payback period of small home appliance assembly lines is usually 1-2 years, and that of large home appliances is 3-5 years; automated assembly can improve production efficiency by 30%-50% and reduce defect rates by 20%-30%.

- Automobiles: The investment payback period of vehicle assembly lines is longer (5-8 years), but automated production can increase per capita capacity by 2-3 times, significantly improve product consistency, and reduce the risk of safety accidents.