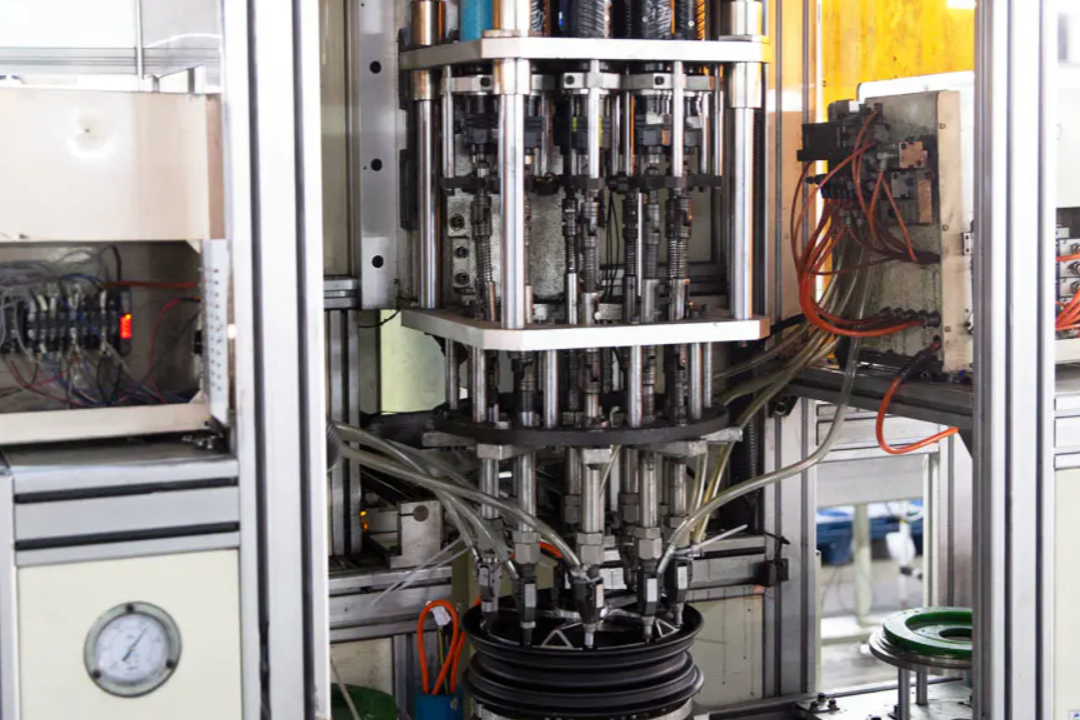

Wheel hub motor multi-axis servo tightening machine

Multi-axis Servo Tightening Machine for Hub Motors

The multi-axis servo tightening machine for hub motors is a high-precision tightening device developed for the assembly scenario of new energy vehicle hub motors. Adopting multi-axis synchronous control technology, it can complete the precise tightening operation of multiple bolts of the hub motor simultaneously. The equipment integrates a servo drive system, torque sensor and intelligent control system, which can real-time monitor key parameters such as torque, angle and speed during the tightening process to ensure the consistency and reliability of hub motor assembly.

Compared with traditional single-axis tightening equipment, the multi-axis servo tightening machine greatly improves the assembly efficiency of hub motors, while effectively reducing manual operation errors, meeting the high-precision and high-consistency assembly requirements of new energy vehicle components.

Multi-axis Synchronous Tightening

Supports 2-8 axis synchronous tightening, completes the assembly of all hub motor bolts in one operation, improves assembly efficiency by more than 60%, and avoids positioning errors caused by multiple tightenings of a single axis.

High-precision Torque Control

Torque control accuracy ±1%, angle control accuracy ±0.5°, meeting the high-precision requirements of hub motor bolt tightening, and eliminating potential safety hazards caused by insufficient torque or over-tightening.

Full-process Data Traceability

Real-time recording of tightening data for each axis, supporting data storage, export and traceability, meeting the quality control requirements of new energy vehicle component assembly.

Adaptive Tooling Compatibility

Adapts to the assembly requirements of hub motors of different specifications, with fast and convenient tooling switching, strong equipment versatility, and reduced production line transformation costs.