Assembly Line Station Calculation Tool

No station data, please add stations

Total Stations: 0

Total Assembly Line Length: 0 m

Max Operation Time: 0 s

Min Operation Time: 0 s

Hourly Capacity: 0 units/hour

Assembly Line Station Calculation Tool – User Manual

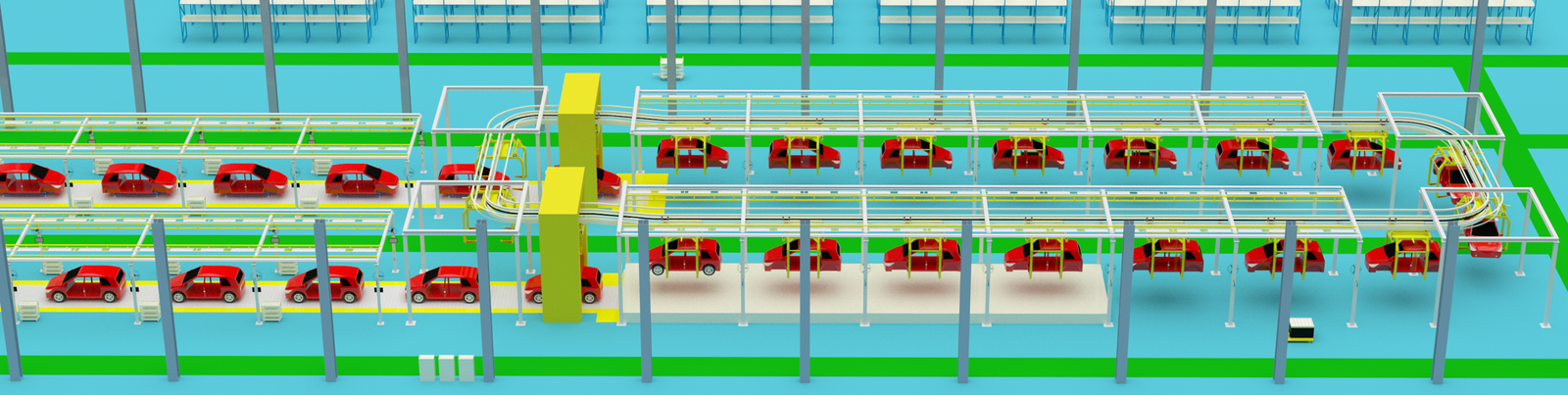

1. Overview

This tool is a web-based application designed for calculating and analyzing assembly line station data. It helps production managers and engineers efficiently track station metrics, visualize operation time distribution, and calculate hourly production capacity—all within a responsive interface that works seamlessly in WordPress columns and across devices (desktop/mobile).

2. Key Features

| Feature | Description |

|---|---|

| Station Data Management | Add, delete, and clear station records with name, length (meters), and operation time (seconds) |

| Real-time Statistics | Automatically calculate total stations, total assembly line length, max/min operation time |

| Visualization | Generate bar charts to compare operation time across all stations |

| Highlight Identification | Visually highlight stations with maximum (yellow) and minimum (green) operation time |

| Capacity Calculation | Automatically compute hourly production capacity based on bottleneck station time |

| Responsive Design | Adapt to different screen sizes (optimized for WordPress column layout) |

3. How to Use

Step 1: Add Station Data

- Enter the Station Name (required, text input)

- Input Station Length (required, numeric value > 0, unit: meters, 0.1 step)

- Input Operation Time (required, numeric value > 0, unit: seconds, 0.1 step)

- Click Add Station to save the record

Step 2: Manage Station Records

- Delete Single Station: Click the “Delete” button next to the target station in the list

- Clear All Data: Click “Clear All” and confirm the pop-up prompt to remove all station records

Step 3: View Statistics & Visualization

- Statistics Section: Check key metrics:

- Total Stations: Number of added stations

- Total Assembly Line Length: Sum of all station lengths (rounded to 1 decimal place)

- Max Operation Time: Longest operation time among all stations (bottleneck station)

- Min Operation Time: Shortest operation time among all stations

- Hourly Capacity: Calculated as 3600 ÷ max operation time (rounded to 2 decimal places, unit: units/hour)

- Chart Section: View the bar chart for visual comparison of operation time per station (x-axis: station names, y-axis: operation time in seconds)

4. Calculation Logic

Hourly Capacity Formula

plaintext

Hourly Capacity = 3600 (seconds per hour) / Maximum Operation Time (seconds per unit)

Note: The maximum operation time determines the bottleneck of the assembly line, which directly limits the overall hourly production capacity.

5. Technical Notes

- Font: Uses open-source Source Han Sans (no commercial copyright restrictions)

- Chart Library: Integrates Chart.js v4.4.8 (open-source, non-commercial use)

- Compatibility: Works on all modern browsers (Chrome, Firefox, Safari, Edge)

- WordPress Integration: Can be directly embedded via WordPress “Custom HTML” block (100% width adaptive)

6. Error Handling

The tool includes input validation to ensure data accuracy:

- Empty station name → Alert prompt

- Non-numeric/zero/negative length/time → Alert prompt

- Confirmation required for clearing all data to prevent accidental deletion