Customized small-scale automobile assembly production line SKD CKD

Small-scale vehicle assembly line customization offers flexible, cost-effective solutions for overseas markets with limited capacity and investment. These modular, semi-automated production lines (1,000–10,000 units/year) adapt to local conditions like unstable power, limited skilled labor, and strict import regulations. By utilizing CKD assembly, simplified logistics, and progressive automation, manufacturers can establish sustainable operations in developing regions while meeting government localization requirements and minimizing financial risk.

Detailed Explanation: Small-Scale Automobile Assembly Line Customization for Overseas Markets

I. What is Small-Scale Vehicle Assembly?

Core Characteristics:

| Dimension | Small-Scale Line | Traditional Mass Production |

|---|---|---|

| Annual Capacity | 1,000 – 10,000 units | 100,000+ units |

| Floor Area | 5,000 – 20,000 m² | 100,000+ m² |

| Investment | US$5M – 30M | Hundreds of millions |

| Automation | Semi-automatic or manual-assisted | Highly automated robotics |

| Flexibility | High (multi-model capable) | Low (single model focused) |

| Construction Period | 6 – 12 months | 2 – 3 years |

II. Typical Target Markets

Market Characteristics:

- Developing regions: Africa, Southeast Asia, Central Asia, Latin America

- Limited market size: Annual sales of thousands to tens of thousands

- High import tariffs: CKD (Complete Knock Down) assembly enjoys lower duty rates than CBU (Completely Built Up)

- Local content requirements: Government mandates for domestic assembly ratios

- Capital and technical constraints: Insufficient funds and skilled workforce for large-scale plants

Regional Adaptations:

| Region | Local Conditions | Recommended Approach |

|---|---|---|

| Africa (Ethiopia, Nigeria, etc.) | Poor infrastructure, unstable power | Minimal manual line with backup generators |

| Southeast Asia (Myanmar, Cambodia, etc.) | Low labor costs, limited skills | Semi-automatic line with extensive training programs |

| Central Asia (Uzbekistan, Kazakhstan, etc.) | Geographic advantages, transit trade | Flexible multi-model production |

| Latin America (Bolivia, Paraguay, etc.) | Mountainous terrain, logistics challenges | Compact modular layout design |

III. Customization Solutions

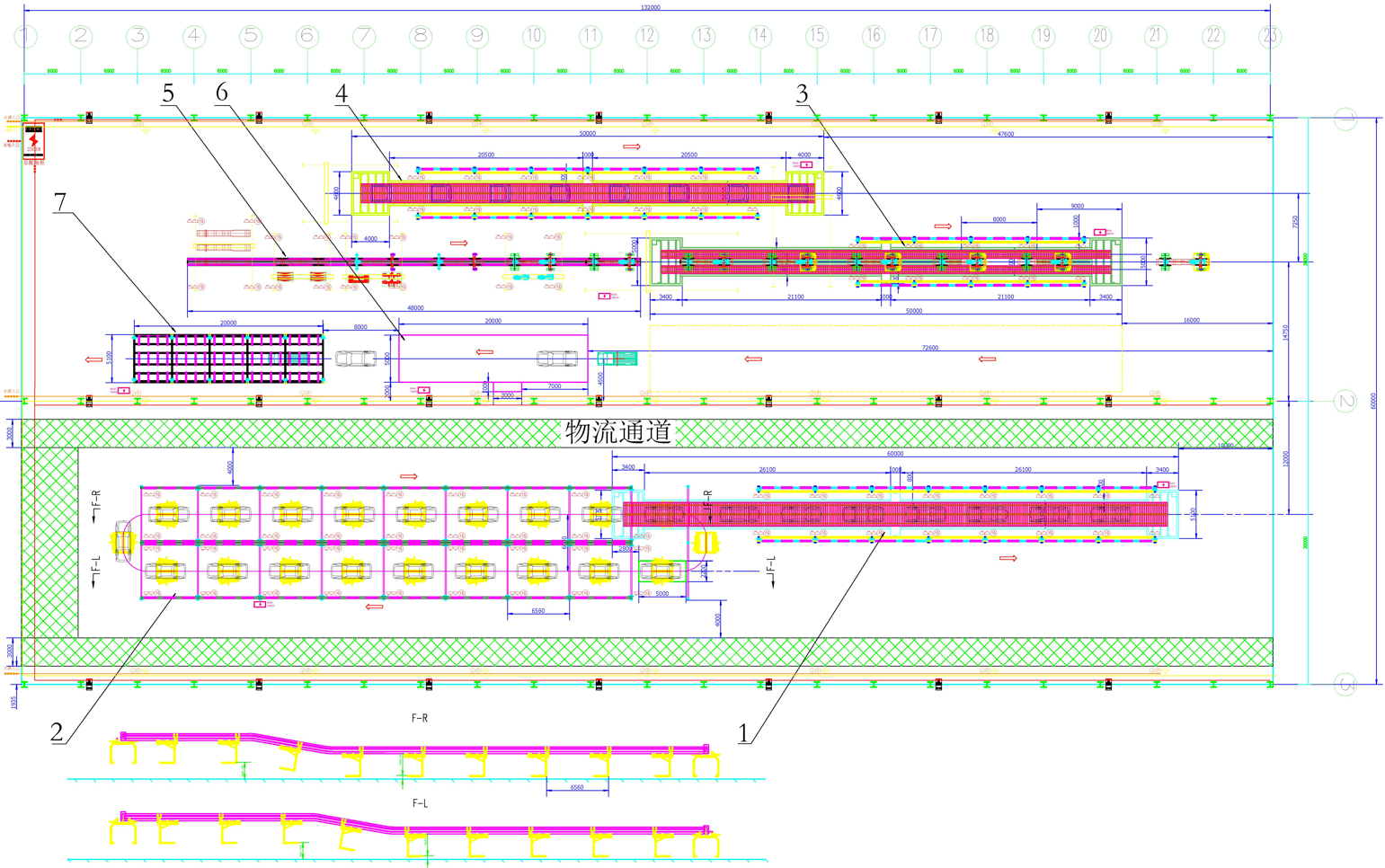

1. Layout Options

A. Linear Layout (Simplest)

- Configuration: Straight line with single-side material supply

- Capacity: 1,000 – 3,000 units/year

- Workforce: 30 – 50 operators

- Investment: US$5M – 8M

B. U-Shaped Layout (Recommended)

- Configuration: Space-efficient, manageable, scalable

- Capacity: 3,000 – 8,000 units/year

- Workforce: 50 – 100 operators

- Investment: US$8M – 15M

C. Modular Island Layout (Most Flexible)

- Configuration: Independent workstations with central logistics, parallel processing capability

- Capacity: 5,000 – 10,000 units/year

- Workforce: 80 – 150 operators

- Investment: US$15M – 30M

2. Key Workstation Configuration

| Workstation | Equipment | Automation Level | Notes |

|---|---|---|---|

| Body Storage | Simple lifts/forklifts | Manual | Buffer zone based on capacity |

| Interior Trim | Adjustable skids + tool tracks | Semi-automatic | Ergonomic design |

| Chassis Marriage | Hydraulic platforms + fixtures | Semi-automatic | Critical for precise alignment |

| Tire Fastening | Torque wrenches/single-spindle nutrunners | Semi-automatic | Critical torque control |

| Fluid Filling | Vacuum filling equipment (brake, coolant, refrigerant) | Automatic | Essential for quality |

| Inspection Line | Wheel alignment + brake tester + emissions | Automatic | Meet local regulations |

| Road Test | Simple test track | Manual | 500m – 1,000m track length |

3. Logistics Solutions (for Weak Infrastructure)

Core Strategy: Simplified Logistics

- Standardized packaging: CKD parts in reusable metal containers serving as both shipping and line-side storage

- Dense storage: Vertical racks or narrow-aisle shelving to maximize space utilization

- Manual handling priority: Forklifts and pallet jacks reduce automation dependency

- Local sourcing: Tires, batteries, seats sourced locally to minimize CKD volume

Typical Logistics Flow:

Overseas supplier → Container sea freight → Port customs clearance → Plant warehouse → Unpacking/inspection → Line-side delivery → Workstation assembly

Critical components maintain 3–5 days safety stock to mitigate customs delays

IV. Customization Service Essentials

1. Localization Adaptations

| Local Condition | Custom Solution |

|---|---|

| Unstable power | Diesel generators + UPS for critical equipment (e.g., electrical testers) |

| High heat/humidity | Enhanced ventilation, corrosion-resistant equipment, climate-controlled paint shop |

| Limited skilled labor | Error-proofing fixtures (Poka-Yoke), comprehensive training, visual work instructions |

| Terrain constraints | Modular steel structure buildings adaptable to uneven ground |

| Special regulations | Inspection lines tailored to local standards (LHD/RHD, emission levels, safety codes) |

2. Flexible Investment Models

| Model | Description | Suitable For |

|---|---|---|

| Turnkey Project | Design through commissioning, full package | Investors with no prior experience |

| Technology License + Equipment Supply | Technology and core equipment provided, client builds facility | Clients with some industrial base |

| Joint Venture | Chinese technical investment, local partner capital contribution | Markets requiring local partnership |

| Phased Investment | Start with SKD (Semi-Knock Down), upgrade to CKD | High market uncertainty |

3. Product Adaptability

Small-scale lines offer superior flexibility:

- Multi-model capability: Sedans, SUVs, pickups, light commercial vehicles

- LHD/RHD switching: Quick changeover via fixture adjustments for different markets

- Powertrain versatility: ICE (Internal Combustion Engine) + NEV (New Energy Vehicle) compatible, with reserved battery pack stations for hybrid/EV expansion

V. Key Success Factors

- Accurate needs analysis: Avoid copying Chinese models; conduct thorough local market, regulatory, and supply chain research

- Strong local support: Reliable local partners for government relations, logistics, and after-sales service

- Continuous technical support: Chinese technicians on-site for 1–2 years to develop local teams

- Spare parts assurance: Establish overseas spare parts inventory to ensure production continuity

- Progressive upgrading: Prioritize operational startup over initial efficiency; automate gradually based on sales growth