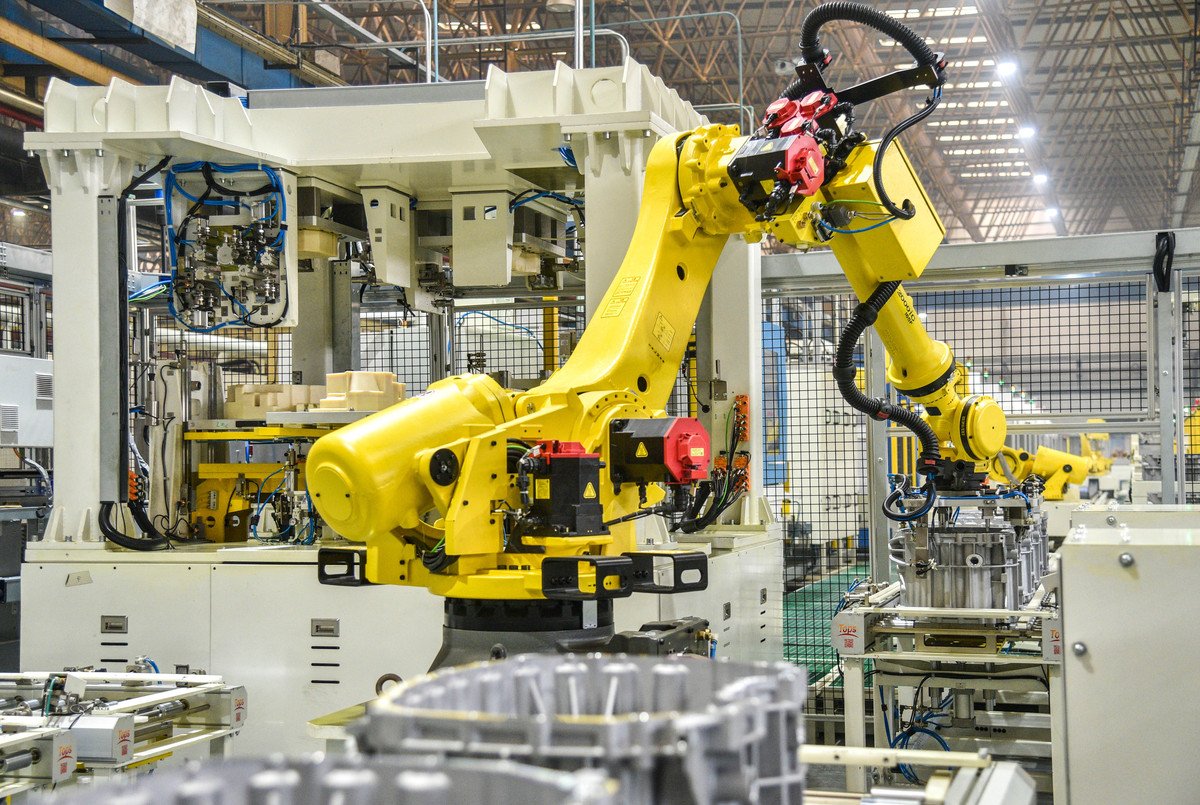

Daily maintenance of industrial robots on assembly lines

Daily maintenance is crucial for ensuring the stable operation, efficiency and safety of industrial robots on assembly lines, which can reduce failure rates and extend service life. Classified by cycles (daily, weekly, monthly, quarterly and annual), maintenance mainly includes appearance inspection, operational status monitoring, cleaning, lubrication, fastening, component inspection and replacement, as well as calibration of sensors and motion accuracy. The summary table facilitates quick reference, while general precautions emphasize safe operation, adherence to manual requirements, sound record-keeping and professional training for personnel to handle faults properly.

Detailed Instructions for Daily Maintenance of Industrial Robots on Assembly Lines

In the assembly line production scenario, industrial robots, as core equipment, their operational stability directly affects production efficiency, product quality, and production safety. Daily maintenance is a key means to ensure the long-term reliable operation of industrial robots. Through systematic inspection, cleaning, lubrication, adjustment, and replacement of components, it can effectively reduce the failure rate, extend the service life of the equipment, and ensure the continuous and stable operation of the assembly line. This instruction will classify by maintenance cycle, elaborate on the specific content of daily maintenance of industrial robots on assembly lines in detail, and attach a summary table for quick reference.

I. Daily Maintenance (Daily/Per Shift)

Daily maintenance is basic maintenance work, which needs to be carried out in stages before, during, and after each shift’s production. It focuses on the equipment’s appearance, operational status, and basic conditions of key parts to promptly detect and handle minor abnormalities.

- Appearance Inspection: Check whether the robot body, control cabinet, teach pendant, and cables are damaged, deformed, loose, or otherwise defective; inspect the equipment surface for accumulation of oil stains, dust, iron filings, and other debris, paying special attention to key parts such as moving joints and terminal blocks.

- Operational Status Monitoring: After starting the robot, observe whether each axis moves smoothly, and if there are any abnormal noises, vibrations, or jamming phenomena; check whether the parameters displayed on the teach pendant (such as motor temperature, joint angle, air pressure value, etc.) are within the normal range; monitor the operation of the fans in the control cabinet to ensure normal heat dissipation.

- Cleaning Work: Wipe the robot body, teach pendant screen, and control cabinet surface with a clean cloth to remove debris and oil stains; gently blow the dust-prone parts such as gaps of moving joints and cable connectors with compressed air (note that the air pressure should not be too high to avoid damaging components).

- Safety Device Inspection: Confirm that safety protection devices such as emergency stop buttons, safety doors, and light curtains are normal and effective. The robot should stop running immediately when the emergency stop button is pressed, and the equipment should trigger an alarm and shut down when the safety door is opened.

- Air Supply Inspection: If the robot is equipped with pneumatic fixtures or pneumatic components, check whether the air supply pressure meets the requirements, and whether there is air leakage at the air pipe connectors. Replace damaged air pipes or loose connectors in a timely manner.

II. Weekly Maintenance

On the basis of daily maintenance, weekly maintenance further deepens the inspection scope, focusing on the lubrication status, fastening conditions, and initial signs of wear of some key components.

- Lubrication Inspection and Supplement: Check the grease level of each moving joint. If the level is lower than the specified standard, promptly supplement the corresponding type of grease; check whether the lubrication pipeline is unobstructed and whether there is blockage or leakage.

- Fastening Inspection: Use appropriate tools to check whether the connecting bolts, nuts (such as joint connections, base fixing bolts), cable fixing buckles, and terminal blocks in the control cabinet of the robot body are loose, and tighten the loose parts (note to follow the specified torque value to avoid over-tightening or under-tightening).

- Teach Pendant and Cable Inspection: Check whether the buttons of the teach pendant are sensitive, the display is clear, and the response of the touch screen (if any) is accurate; check whether the cables are aging or cracked, and whether there is excessive wear at the cable bends to ensure that the cables are firmly connected and routed standardly.

- Filter Device Inspection: Clean the filter element of the air filter. If the filter element is severely damaged or blocked, replace it in a timely manner; check the filter of the hydraulic system (if any) for accumulation of impurities.

III. Monthly Maintenance

Monthly maintenance requires a more comprehensive inspection of the operating conditions of each system of the equipment, focusing on evaluating the wear degree of components, conducting targeted inspections on vulnerable parts, and ensuring stable equipment performance.

- Motor and Reducer Inspection: Monitor the motor operating temperature and noise. If the temperature rises abnormally (exceeding the specified value) or the noise increases, it is necessary to investigate whether there are problems such as poor lubrication, excessive load, or component wear; check the sealing condition of the reducer for lubricating oil leakage, and supplement lubricating oil if necessary.

- Sensor Inspection: Calibrate and functionally test the position sensors, force sensors, vision sensors, etc. equipped with the robot to ensure accurate sensor signals and stable transmission, and promptly clean debris on the sensor detection surface.

- Internal Inspection of Control Cabinet: Open the control cabinet, check whether the internal lines are loose, aging, or ablated; clean the dust inside the control cabinet (using compressed air or a vacuum cleaner); check the operating status of electrical components such as power modules, drives, and contactors, and observe whether the indicator lights are normal.

- Fixture Maintenance: Check whether the end fixtures of the assembly line robot (such as grippers, suction cups, etc.) are worn or deformed, and whether the clamping force of the fixtures meets the requirements. Replace or repair severely worn fixture components, and adjust the clamping accuracy.

IV. Quarterly Maintenance

Quarterly maintenance is in-depth maintenance, which needs to comprehensively inspect and maintain core components in combination with equipment operation data, promptly detect and handle potential faults, and ensure the long-term stable operation of the equipment.

- Comprehensive Inspection of Lubrication System: Fully lubricate components such as reducers and bearings of each moving joint, replace grease or lubricating oil according to the equipment manual requirements; check the working status of the lubrication pump to ensure normal pressure and stable oil supply of the lubrication system.

- Transmission Component Inspection: Check whether the transmission components such as gears, belts, and chains of the robot are worn, deformed, or loose. Replace severely worn components, and adjust the tension of belts or chains to the specified range.

- Electrical System Detection: Use professional instruments to detect whether the power supply voltage and current are stable, and check whether the output parameters of the drive are normal; check the battery in the control cabinet, and replace it in a timely manner if the battery power is insufficient (to avoid program loss); test the insulation performance of each electrical circuit to ensure no short circuit or leakage risk.

- Motion Accuracy Calibration: Use high-precision equipment such as laser trackers to calibrate the motion accuracy of the robot. If the accuracy deviation exceeds the specified value, adjust it through the teach pendant or control system to ensure that the assembly accuracy meets the production requirements.

V. Annual Maintenance

Annual maintenance is a comprehensive inspection and maintenance work, which needs to thoroughly inspect, test, and evaluate each system and component of the robot, replace aging components or those close to the service life, and lay a foundation for the stable operation of the equipment in the next year.

- Disassembly Inspection of Core Components: According to the equipment operation years and manual requirements, disassemble and inspect core components such as reducers, motors, and bearings, check the wear and corrosion of internal parts, and repair or replace them if necessary.

- Comprehensive Detection of Control System: Comprehensively detect the software and hardware of the control system, update the system software (if there is a new version), and back up equipment programs and parameters; check the performance of key electrical components such as motherboards and storage modules to ensure the stable and reliable operation of the control system.

- Comprehensive Test of Safety System: Conduct comprehensive tests on the emergency stop system, safety interlock system, alarm system, etc., simulate various fault scenarios, check the response speed and reliability of safety devices, and ensure compliance with safety standards.

- Overall Equipment Evaluation and Maintenance Record Collation: Evaluate the overall operating status of the robot, summarize the annual fault situation and maintenance experience, and formulate the maintenance plan for the next year; collate the annual maintenance records and establish a complete equipment maintenance file.

VI. Summary Table for Daily Maintenance of Industrial Robots on Assembly Lines

| Maintenance Cycle | Core Maintenance Content | Maintenance Requirements | Precautions |

| Daily/Per Shift | 1. Appearance inspection (body, control cabinet, cables); 2. Operational status monitoring (motion, noise, parameters); 3. Cleaning work; 4. Safety device inspection; 5. Air supply inspection (if any) | Promptly detect minor abnormalities and ensure good basic status of the equipment | Avoid directly flushing electrical components with water during cleaning; reset according to the specified process after pressing the emergency stop button |

| Weekly | 1. Lubrication inspection and supplement; 2. Fastening of various connecting parts; 3. Detailed inspection of teach pendant and cables; 4. Cleaning of filter devices | Ensure sufficient lubrication and firm connection, and eliminate potential loosening and wear hazards | Follow the specified torque value when tightening bolts; control the air pressure at 0.3-0.5MPa when blowing with compressed air |

| Monthly | 1. Comprehensive inspection of motor and reducer; 2. Sensor calibration and functional test; 3. Internal inspection and cleaning of control cabinet; 4. Fixture maintenance (accuracy, clamping force) | Ensure stable performance of core components, accurate sensor signals, and qualified fixture accuracy | Cut off the power supply and wait for capacitor discharge before opening the control cabinet; use standard tools for sensor calibration |

| Quarterly | 1. Comprehensive maintenance of lubrication system (grease/oil replacement); 2. Inspection and replacement of transmission components; 3. Electrical system detection (voltage, insulation, battery); 4. Motion accuracy calibration | In-depth maintenance of core systems to ensure motion accuracy and electrical safety | Select the grease specified in the equipment manual for replacement; accuracy calibration should be performed by professional personnel |

| Annual | 1. Disassembly inspection and replacement of core components; 2. Comprehensive detection and software update of control system; 3. Comprehensive test of safety system; 4. Collation of maintenance records and annual evaluation | Comprehensively investigate equipment hazards, replace aging components, and establish a complete maintenance file | Follow the equipment disassembly process when disassembling core components; back up key programs and parameters before updating system software |

VII. General Precautions

- All maintenance work shall be carried out after the equipment is shut down and the power and air supply are cut off (except for special inspections) to ensure the safety of operators.

- During maintenance, strictly follow the requirements of the equipment manual, select accessories, lubricants, tools, etc. that meet the specifications to avoid damaging the equipment due to improper use.

- Establish a sound maintenance record system, and detailedly record the maintenance time, maintenance content, found problems, and handling results to facilitate tracing the equipment operation history and formulating subsequent maintenance plans.

- Maintenance personnel shall receive professional training, be familiar with the structure, principle, and operation specifications of the robot, and master basic fault judgment and handling skills.

- If major faults (such as severe wear of core components, electrical system faults, etc.) are found during maintenance, stop the maintenance work immediately, hang warning signs, and contact professional maintenance personnel for handling.