How to improve the assembly efficiency of electric motorcycles

Electric motorcycle assembly efficiency requires blending Lean Manufacturing’s waste elimination and quality-built-in philosophy with Assembly Line’s standardized takt and automation. This integration—termed “Lean Line”—combines continuous flow, error-proofing, and JIT pull systems with balanced workstations and intelligent logistics. The result delivers superior productivity, minimal inventory, high first-pass yield, and flexibility to handle diverse models, making it optimal for the rapidly evolving electric vehicle industry.

I. Core Philosophy Comparison

| Dimension | Lean Manufacturing | Assembly Line |

|---|---|---|

| Primary Goal | Eliminate waste, create value flow | Standardize operations, maximize output speed |

| Focus | End-to-end value stream optimization | Single-point efficiency maximization |

| Inventory Strategy | Zero inventory / Just-in-Time (JIT) | Buffer inventory to ensure continuity |

| Quality Philosophy | Jidoka (autonomation), error-proofing at source | End-of-line inspection, rework mechanism |

| People’s Role | Multi-skilled workers, continuous improvement | Specialized division of labor, standard execution |

| Improvement Driver | Pull-based, problem-driven | Push-based, capacity-driven |

II. Specific Measures for Electric Motorcycle Assembly Efficiency Improvement

🔧 Lean Manufacturing-Oriented Measures

1. Value Stream Mapping (VSM) and Waste Elimination

- Identify Seven Wastes: Common examples in electric motorcycle assembly include—

- Waiting waste: Battery pack and frame arrival time mismatch

- Transportation waste: Multiple handling of heavy components like motors and controllers

- Inventory waste: Excessive plastic parts堆积 at pre-assembly stations

- Over-processing: Unnecessary screw locking operations

- Continuous Flow Layout: Reorganize frame welding → electrophoretic coating → final assembly → inspection into U-shaped lines, reducing logistics distance by 50%+

2. Just-in-Time (JIT) Production

- Kanban Pull: Final assembly stations send pickup signals to upstream processes (battery modules, motor pre-assembly) based on order demand

- Small Batch Turnover: Reduce batch size from 100 to 20 units, compress changeover time to under 10 minutes through SMED

3. Jidoka (Autonomation) – Quality Built-In

- Error-Proofing Design (Poka-Yoke):

- Unique battery connector shapes to prevent reverse polarity

- Torque guns integrated with MES system, automatic line stop for missed screws

- Andon System: Immediate cord-pull for station abnormalities, response time <30 seconds

4. Total Productive Maintenance (TPM)

- Track Overall Equipment Effectiveness (OEE), establish preventive maintenance for electric motorcycle-specific equipment like airtightness testers and hub motor test benches

5. Continuous Improvement Culture (Kaizen)

- Monthly “improvement proposal” mechanism, e.g., optimizing wire harness routing to reduce interference, adjusting footrest installation sequence to reduce fatigue

⚙️ Assembly Line-Oriented Measures

1. Work Decomposition and Takt Time Balancing

- Takt Time Calculation: For 300 units/day, 8-hour shift, takt = 96 seconds/unit

- Work Balance Wall: Decompose electric motorcycle assembly into:

- Frame loading → Motor hoisting → Battery pack assembly → Controller wiring → Front wheel assembly → Instrument installation → Final inspection

- Bottleneck Elimination: Compress longest workstation to within takt time through ECRS (Eliminate/Combine/Rearrange/Simplify)

2. Standardized Work (SOS)

- Three-Document System: Work instructions + Standard WIP + Takt time chart

- Motion Economy Principles: Tools on balancers, pick-and-place distance <30cm; adjustable seat height to reduce bending

3. Rigid Automation Integration

- Automation Cells:

- Automatic tire tightening machine (torque accuracy ±3%)

- AGV automatic delivery of battery packs to workstations

- Automatic headlight gap inspection station

- Rigid Takt: Constant-speed conveyor, fixed operation window per station

4. Specialized Division of Labor

- Skill Segmentation: Strict separation of wiring workers, assembly workers, debugging workers, inspection workers

- Learning Curve Effect: 30-40% efficiency improvement after 500 repetitions of single motion

III. Key Scenario Comparative Analysis

表格

复制

| Scenario | Lean Manufacturing Solution | Assembly Line Solution | Integration Recommendation |

|---|---|---|---|

| High-mix Low-volume (custom models, export orders) | Cell units, quick changeover | Dedicated lines, high changeover loss | Flexible Assembly Line: Modular design + quick fixture switching |

| Critical Quality Points (battery safety, braking system) | Source error-proofing, 100% inspection | End sampling, batch risk | Autonomation Stations: 100% torque monitoring + traceability for critical points |

| Supply Chain Volatility (chip shortage, lithium price fluctuation) | Heijunka (production leveling), reduced fluctuation | Inventory buffer, capital tie-up | Strategic Inventory + JIT: Stock long-lead items, pull short-lead items |

| Labor Cost | Multi-skilled worker training, high investment | Simple training, quick onboarding | Human-Machine Collaboration: Manual for complex tasks, robots for repetitive/heavy tasks |

| Capacity Ramp-up | Gradual optimization, low risk | One-time investment, quick results | Modular Capacity: Scalable workstation design |

IV. Modern Electric Motorcycle Manufacturing: Lean Line Paradigm

Current industry best practice is integration rather than opposition:

Key Integration Points

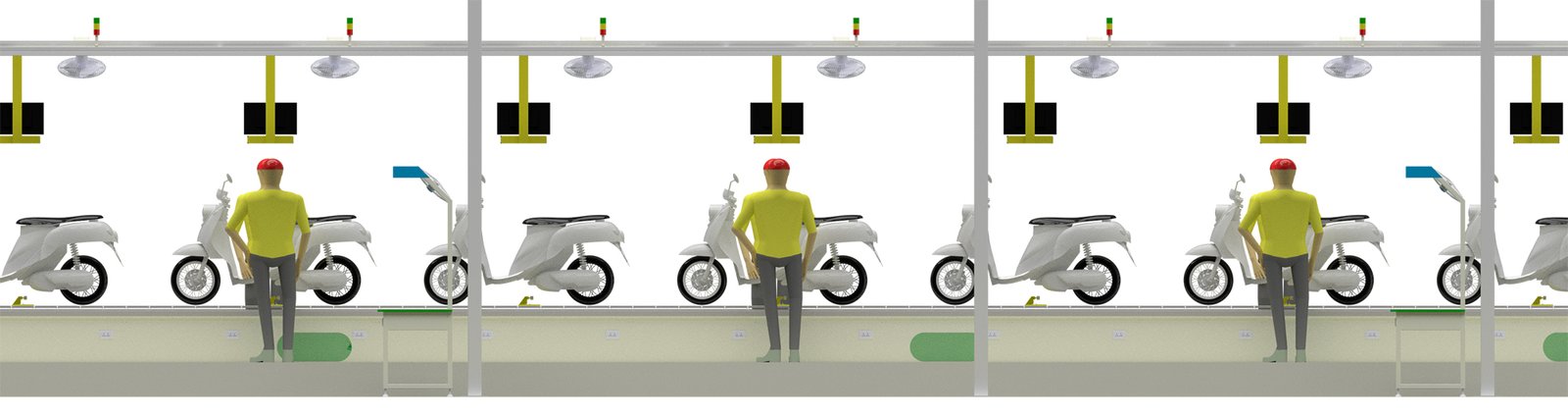

- Flexible Hardware: Workstations use quickly reconfigurable aluminum extrusion frames to adapt to different wheelbase models

- Intelligent Logistics: AGVs replace conveyors, dynamically adjusting delivery routes based on real-time takt

- Digital Twin: Virtual commissioning of changeover schemes, reducing physical changeover time from 4 hours to 30 minutes

- Optimal Human Efficiency: Retain manual flexibility (wire harness arrangement, appearance inspection), robots handle heavy-load/precision operations

V. Quantified Efficiency Improvement Comparison

表格

复制

| Metric | Traditional Assembly Line | Pure Lean Cell | Lean Line Integration |

|---|---|---|---|

| Units Per Hour per Person (UPH) | 2.5 | 2.0 | 3.2 |

| Work-in-Process Inventory (WIP) | 80 units | 5 units | 12 units |

| First Pass Yield (FPY) | 92% | 98% | 99.2% |

| Changeover Time | 4 hours | 15 minutes | 25 minutes |

| Floor Space Utilization | 65% | 85% | 90% |

| Employee Multi-Skill Rate | 20% | 80% | 60% |

VI. Implementation Roadmap

Phase 1 (0-6 months): Establish Flow Foundation

- Value stream analysis, identify top 3 waste sources in electric motorcycle assembly

- Implement 5S and visual management, establish Andon system

Phase 2 (6-12 months): Takt Time and Autonomation

- Design flexible assembly line with balance rate >85%

- Introduce error-proofing and data traceability at critical workstations

Phase 3 (12-24 months): Intelligent Lean

- Implement MES system, achieve closed loop of order-scheduling-execution-traceability

- Introduce collaborative robots, optimize human-machine collaborative takt

Core Insight: The electric motorcycle’s “three-electric system” (battery, motor, controller) features rapid technology iteration and high safety requirements, necessitating a manufacturing system that combines the efficiency stability of assembly lines with the flexible quality built-in capability of lean manufacturing. Pure speed pursuit may lead to batch quality incidents (e.g., battery thermal runaway), while excessive flexibility struggles to meet market explosion demands. The integrated paradigm is the optimal solution for current industrial competition.