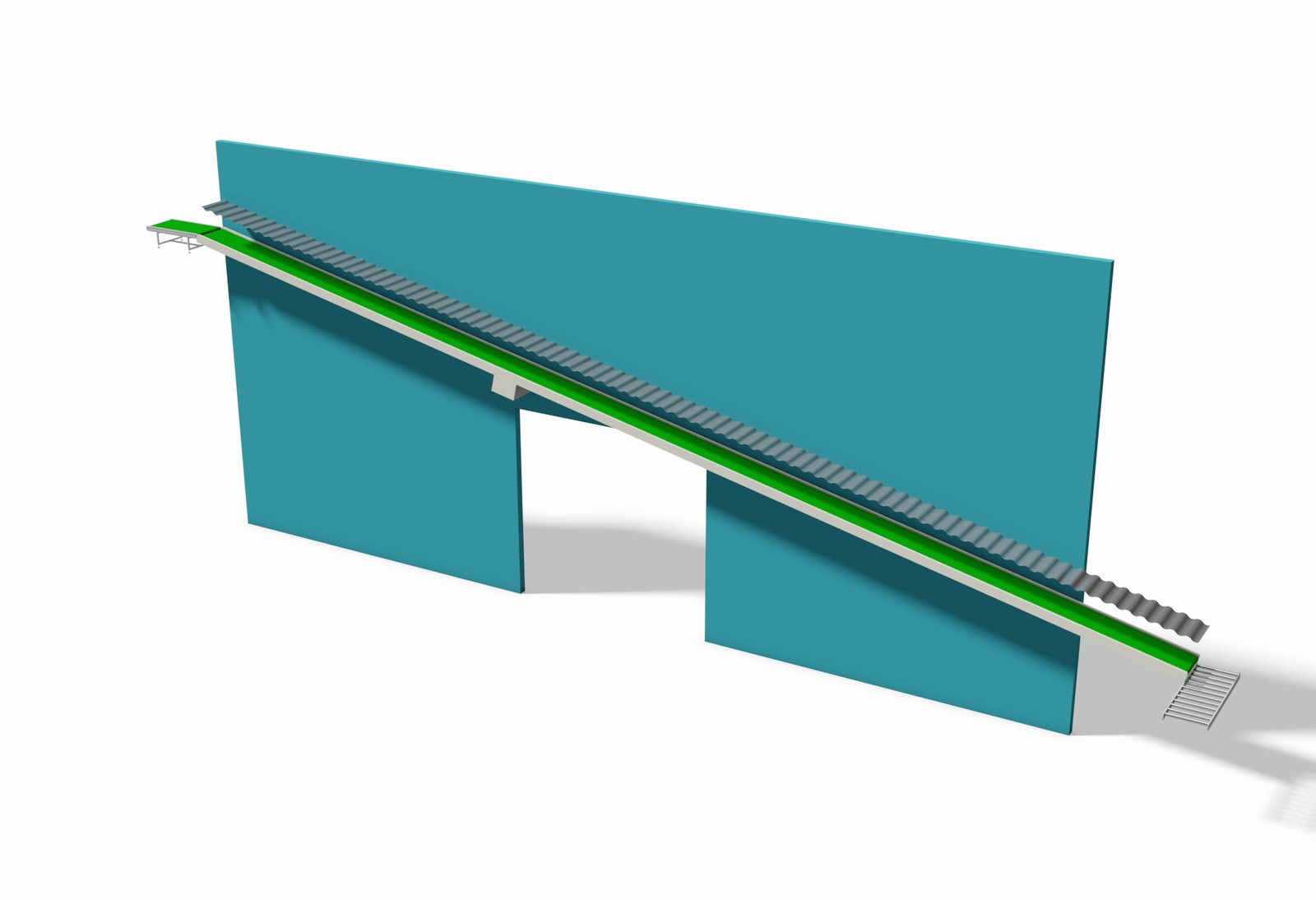

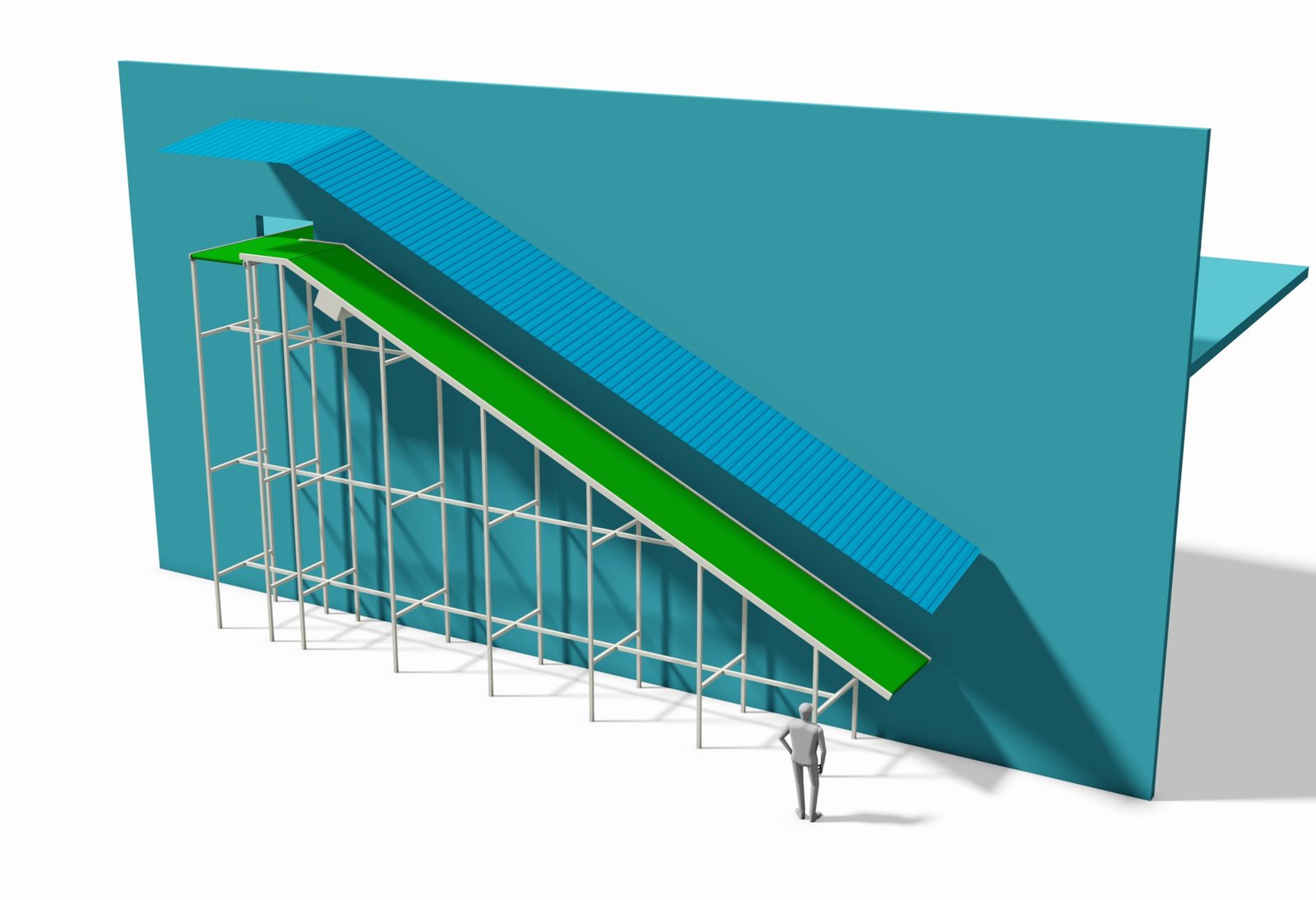

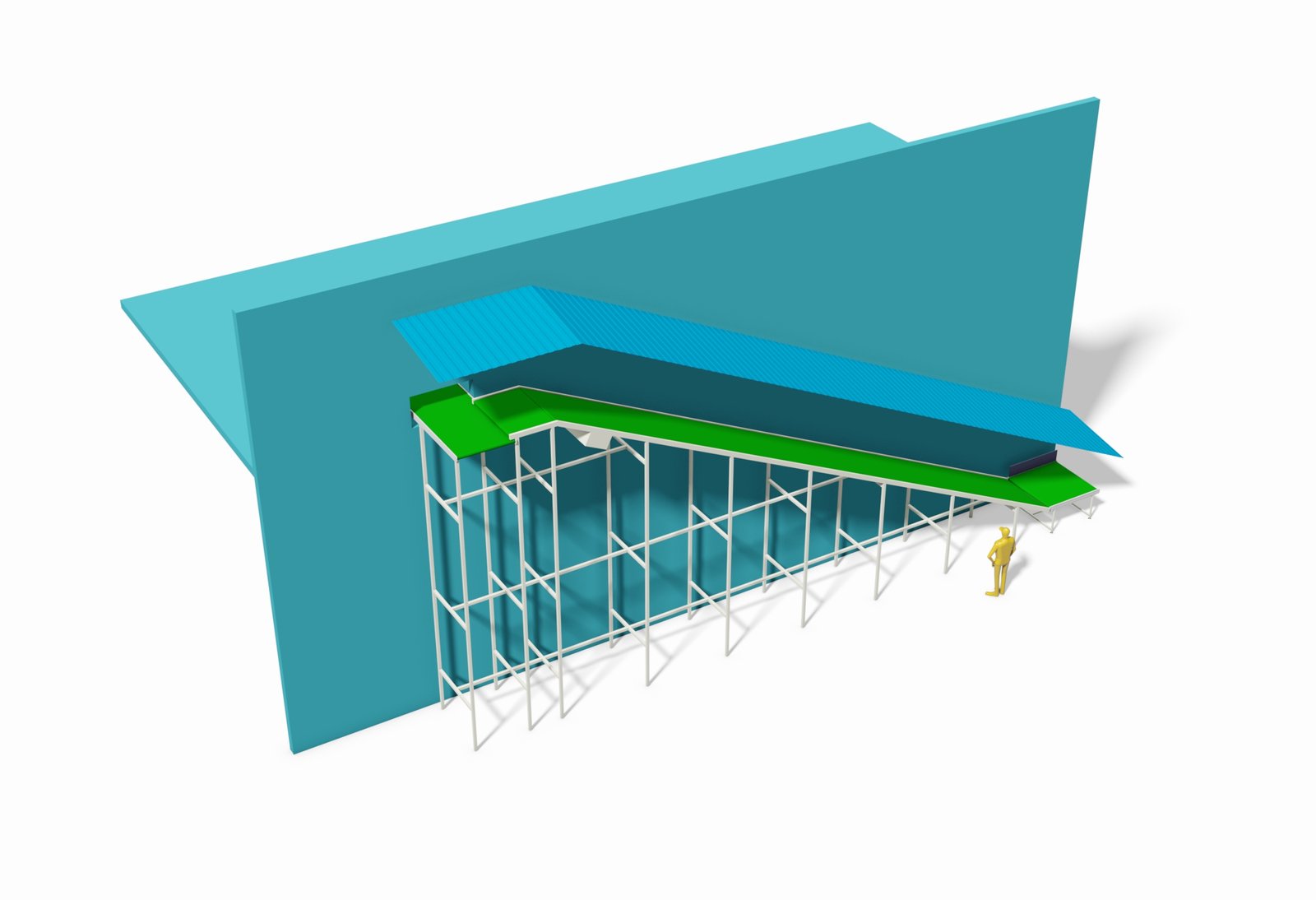

The factory uses an inclined conveyor line that runs from outdoor to indoor.

✅ 1. Equipment Selection & Design Points

- Inclination Angle: Generally recommended not to exceed 25° to ensure stable material transport.

- Belt Type: Use anti-slip climbing belts (e.g., chevron-patterned belts) to prevent materials from sliding on the incline.

- Structural Materials: For outdoor sections, use stainless steel or powder-coated carbon steel for rust and corrosion resistance.

- Protection Design:

- Install side guards and railings to prevent items from falling or personnel from approaching;

- Outdoor parts must be rainproof, dustproof, and sunproof, e.g., by adding protective covers or using waterproof motors.

✅ 2. Installation & Construction Notes

- Foundation Work: Pour a solid foundation for the outdoor section to ensure equipment stability and prevent settling or shifting.

- Height Difference Adaptation: Customize the length and angle of the climbing section based on actual drop to avoid material rollback or motor overload.

- Power & Control Systems:

- Outdoor motors must meet IP55 or higher waterproof/dustproof ratings;

- Cable routing must comply with Temporary Electrical Safety Standards for Construction Sites, with short-circuit and overload protection.

- Transition Section Handling: Seal and waterproof the indoor-outdoor interface to prevent rainwater from entering indoor areas or equipment.

✅ 3. Safety & Code Requirements

- Guardrails & Warnings: Install guardrails and warning signs along both sides to prevent unauthorized access or climbing.

- Emergency Stop Devices: Place emergency stop buttons at key points (e.g., inlets, outlets, bends) for quick response to incidents.

- Grounding & Electrical Safety:

- All electrical equipment must be reliably grounded, with ground resistance ≤10Ω;

- Conduct annual ground resistance tests, especially during dry seasons.

- Fire Safety & Emergency:

- Equip with fire extinguishers if flammable materials are conveyed;

- Indoor sections must comply with building fire codes, with sufficient exits and evacuation routes.

✅ 4. Application Examples

- Floor-to-floor Transport: Suitable for lifting goods from 1F to 2F, widely used in warehouses, logistics centers, and processing workshops.

- Customer Cases:

- Shoe warehouse outbound climbing line;

- Anti-static climbing conveyor for electronics;

- Parcel sorting climbing system in express industry.

✅ Summary & Recommendation

For climbing conveyors running from outdoor to indoor, functional transport is not enough—environmental adaptability and safety are critical. During the design phase, fully consider:

- Environmental differences (wind, rain, temperature swings);

- Material characteristics (weight, shape, flammability);

- Safety codes (electrical, fire, personnel protection);

- Ease of future maintenance.