Agricultural Tricycle Assembly Line

A certain brand’s agricultural tricycle is built with high-strength steel frames, dual-keel reinforcement and leaf-spring suspension to carry one-ton loads across rough fields. Split-type modules and robot welding let any part be swapped or shipped fast, while fire-proof wiring and auto-coating guarantee years of corrosion-free work. On eight smart lines a complete chassis rolls out every 40 seconds: engines, axles, dashboards and dump beds snap together like Lego, inspected by sensors at each station. Nearby suppliers feed tyres, electronics and cargo boxes just-in-time, keeping costs low and spares always ready.

I. Structural Design

- Frame and Chassis

A certain brand of agricultural tricycles generally adopts high-strength steel for the frame, with reinforced key areas to enhance overall rigidity and load-bearing capacity. Some heavy-duty models feature dual keel structures and one-piece welded cargo beds, equipped with reinforcing ribs and bent pipe supports, capable of carrying loads up to 2,000 jin (approximately 1 ton). - Suspension and Shock Absorption System

Many models are equipped with leaf spring suspensions (e.g., 6- or 8-leaf curved ear spring steel plates), improving stability and comfort under heavy loads. - Power System

Electric models often use permanent magnet synchronous motors, with maximum power up to 3,000W, paired with intelligent controllers for efficient output. Fuel-powered models are equipped with the brand’s self-produced engines, offering strong climbing and load-bearing performance. - Functional Features

Includes one-button tipping, dump beds, LED headlights, hydraulic shock absorbers, and drum brake systems, enhancing practicality and safety.

II. Assembly Process

- Welding and Coating

The brand’s production facility uses robotic welding and automated coating lines, ensuring welding precision and uniform coating, thereby improving durability and corrosion resistance. - Modular Assembly

Vehicles adopt a split-type structural design, enabling quick disassembly and reassembly for easier maintenance and transportation. Some models support “arbitrary disassembly and assembly,” adapting to complex environments such as mines and mountainous areas. - Quality Control

Uses automotive-grade main cables and fire-retardant materials, with full-vehicle wiring harnesses protected by double layers of corrugated tubes and tape, enhancing electrical safety.

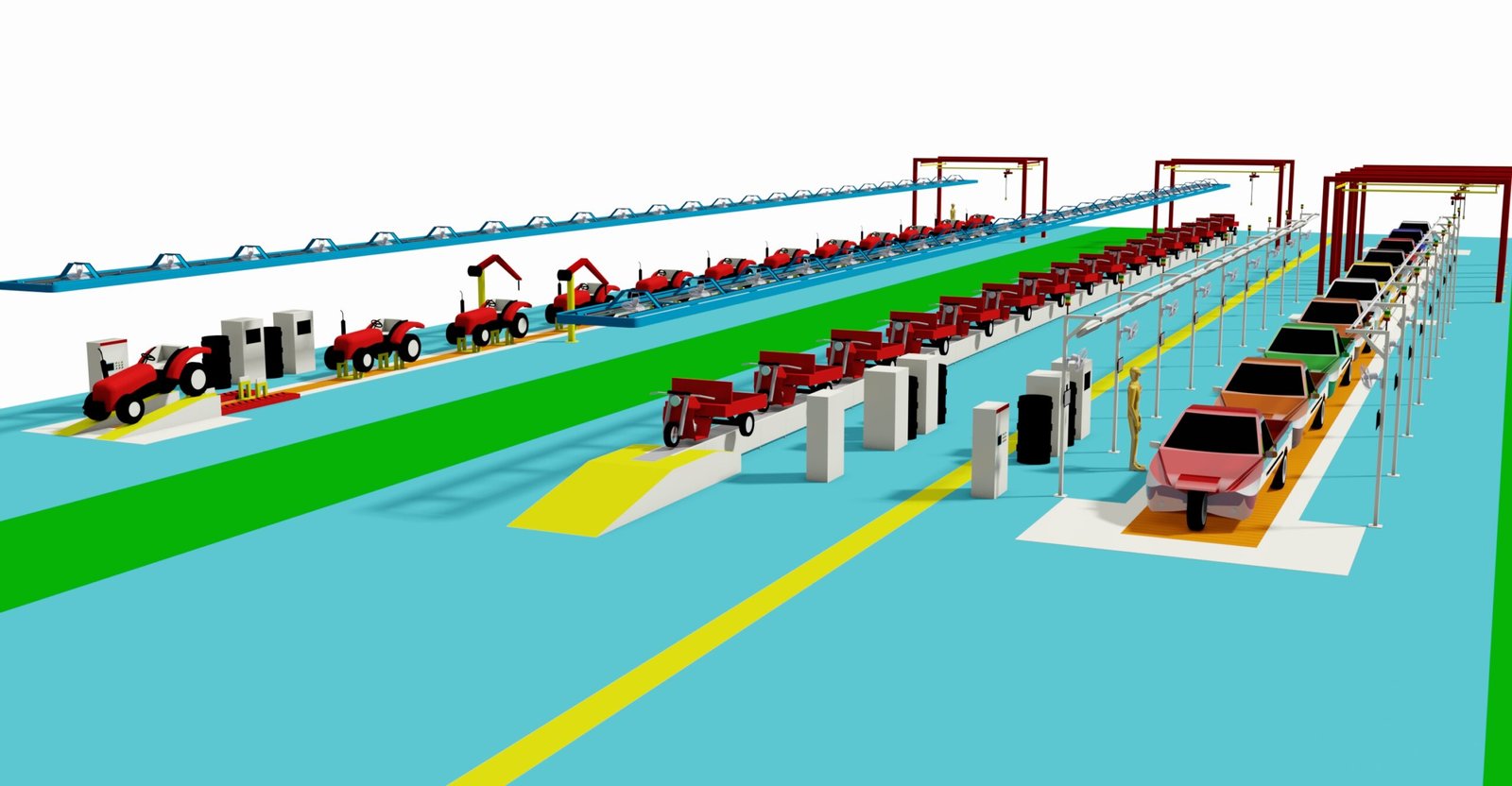

III. Assembly Line

- Smart Production Line

The brand’s smart factory is equipped with 8 high-speed production lines, capable of completing the basic assembly of a vehicle in just over 40 seconds, enabling efficient mass production. - Automation Level

Includes robotic welding, automatic coating, and intelligent inspection processes, improving production efficiency and product consistency. - Industrial Chain Support

The local area has formed a complete tricycle industry chain, allowing the brand to source most components nearby, shortening the supply chain, reducing costs, and improving market responsiveness.

A certain brand of agricultural tricycles emphasizes load capacity and durability in structural design, pursues modularization and automation in assembly processes, and achieves efficient production through intelligent assembly lines. These advantages make their products suitable not only for plain farmlands but also for complex terrains like mountainous and mining areas, establishing them as a key player in agricultural transportation.

The adoption of an assembly line for agricultural three-wheelers transforms scattered, artisanal “back-yard” building into a continuous, industrial-grade replication system. Detailed down to every bolt, torque gun and sensor, its value can be quantified across six axes:

- Efficiency – from “days” to “seconds”

- Takt-time balance splits the vehicle into 180-220 work elements; bottleneck time is locked at 45-50 s, lifting daily output from 30 units in cell-build to 750 on two shifts.

- Parallel sub-lines pre-assemble cabin, rear-axle and engine while the main frame is moving; an overhead cross-transfer merges them in 90 s less than sequential build.

- Four six-axis robots weld 72 floor points in 28 s with 99.5 % first-pass yield, 65 % faster than manual CO₂.

- SPS kit-carts travel with the body, cutting line-side area from 120 m² to 18 m² and daily forklift distance by 42 km.

- Quality – from “experience” to “data”

- Safety-critical torques (hub, steering knuckle, U-bolts) are tightened by servo guns that upload data to MES; ±3 % deviation stops the line automatically.

- RFID + photo-sensors prevent wrong, missing or reversed parts; an unlatched hydraulic hose darkens the ANDON stack-light.

- An in-line four-wheel alignment & brake test rig measures loaded and unloaded states in 40 s; results are bonded to a QR code on the VIN plate.

- Four-code marriage (frame, engine, controller, battery) allows 15-minute batch lock-down, shrinking recall scope by 80 %.

- Cost – from “waste” to “cents”

- Head-count falls from 280 to 68 for the same volume, cutting direct labour per unit by 73 %.

- Robot welding with centralized gas and VFD extraction saves 0.8 kWh per unit; oven waste-heat recovery trims natural-gas use 12 %.

- JIT kanban pulls A-class fasteners to 4-hour inventory, freeing 22 million CNY of cash.

- First-run acceptance rises from 92 % to 98.7 %, reducing rework floor space from 800 m² to 120 m² and saving 32 000 rework hours per year.

- Flexibility – from “dedicated” to “mixed”

- Adjustable hoists and quick-change fixtures allow 1 t, 1.5 t and 2 t payloads, fuel or electric, to be built on the same takt; model change-over <8 min.

- Dealer orders via APP are exploded into BOM in MES; colour, cabin length and brake type can be frozen one hour before build, shortening lead-time by seven days.

- A “double-bay” steel structure with pre-installed robot bases lets capacity grow 30 % by adding only two robots and one station without civil work.

- Safety & ergonomics – from “sweat” to “push-button”

- Manipulators hold 35 kg tyres and 65 kg axles, keeping operator effort ≤15 N·m; scissor lifts eliminate squatting during under-body re-work.

- Fully enclosed welding cells with top + side extraction hold PM2.5 below 0.2 mg/m³, 50 % under the national limit.

- Safety-PLC interlocks on all rotating devices achieve zero lost-time injuries for three consecutive years.

- Data & improvement – from “manufacturing” to “smart”

- A digital twin mirrors the line in real time; engineers drag virtual stations to verify cycle balance before downloading to PLC.

- AI compares current vs. master curves of servo guns and presses, predicting fixture wear or blunt drills and cutting unplanned downtime 35 %.

- Daily Layered Process Audits feed TOP3 issues into A3 reports; PDCA closes them in three days instead of ten.

Collectively, the assembly line is not merely a conveyor but an industrial amplifier that gives low-price agricultural vehicles automotive-grade consistency and traceability. It lets firms scale output rapidly for spring-rush delivery, idle at minimal inventory in off-season, and turn the seeming “impossible triangle” of high quality, low cost and short lead-time into a sustainable competitive moat.