Synchronized Multi-Platform Electric Servo Lift System for Assembly Line

This servo-driven multi-platform synchronous lifting system with worm gear screw jacks is an electromechanical integration solution core-composed of servo motors, worm gear screw jack arrays, and a high-precision synchronous control unit (supporting EtherCAT/Profinet), which converts rotary motion into linear lifting via worm gear transmission and achieves multi-platform synchronization through closed-loop error compensation, with a conventional synchronization accuracy of ±0.1~0.5mm and positioning accuracy of ±0.05~0.2mm. Boasting prominent advantages like excellent mechanical self-locking, stepless speed regulation, low energy consumption (zero standby power), minimal maintenance (no oil leakage, only regular greasing), compact modular layout and fast electric signal response, it is highly adaptable to clean, medium-heavy load industrial scenarios such as automated assembly lines and precision testing with high synchronization demands.

Servo Lifting Platform with Multi-Platform Synchronization Driven by Worm Gear Screw Jacks: Structure, Advantages and Comparison with Hydraulic Type

The servo lifting platform with multi-platform synchronization driven by worm gear screw jacks is an electromechanical integrated device that achieves high-precision synchronous lifting of multiple lifting platforms by taking worm gear screw jacks as the core executive units, combined with servo motor drive and multi-axis synchronous control system. It relies on the mechanical transmission characteristics of worm gears and the precise control of the servo system, and is suitable for lifting requirements with multi-station and high synchronization in industrial automation (such as assembly lines, testing platforms, material conveying and positioning scenarios). The following elaborates on its structure, core advantages and full-dimensional comparison with hydraulic lifting platforms.

I. Core Structure of the Servo-driven Worm Gear Screw Jack Multi-Platform Synchronous Lifting Platform

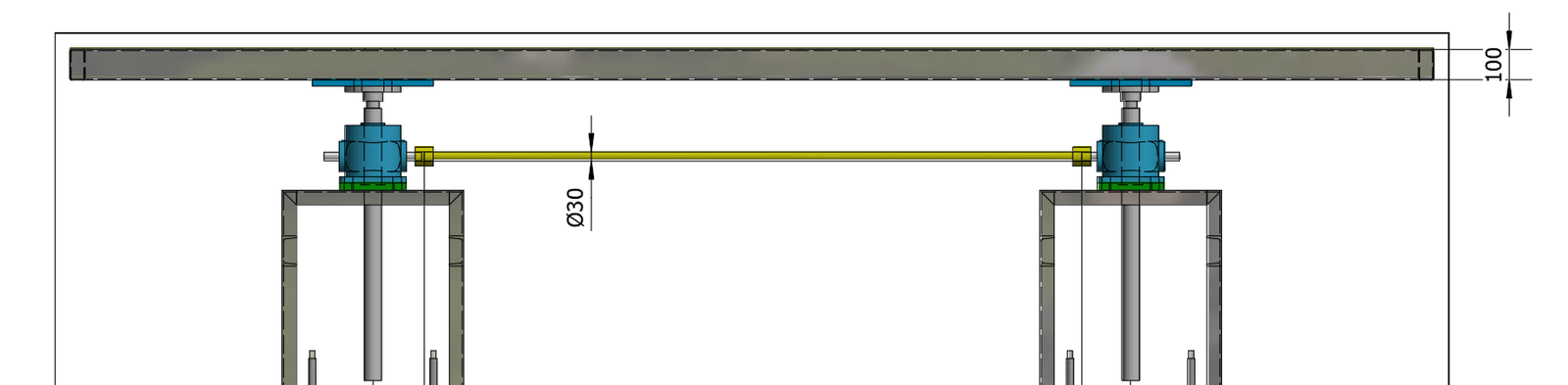

The whole adopts a modular structure of “servo drive system + synchronous control unit + worm gear screw jack array + lifting platform + auxiliary support/guide mechanism”. All parts cooperate to realize the synchronous movement of multiple platforms. The functions and layout of the core components are as follows:

- Servo drive unit: A servo motor (including a servo driver) is used as the power source, which can accurately adjust the speed, torque and positioning, and connect to the input end of the worm gear screw jack directly or through a coupling/reducer to provide independent and controllable power for each jack. For multi-platform solutions, a single servo motor can drive multiple jacks in linkage (through a transmission shaft/timing belt) or a multi-servo motor distributed drive (with a bus-type synchronous control system) can be adopted, and the latter has higher synchronization precision.

- Core of worm gear screw jack: As the actuator, multiple worm gear screw jacks of the same specification are evenly arranged under each lifting platform (e.g., one jack at each of the four corners of a single platform, and arranged according to workstations for multi-platforms). The rotation of the worm drives the worm gear to rotate, converting the rotary motion of the motor into the linear reciprocating motion of the lifting rod of the jack, and directly pushing/pulling the lifting platform. Ball screw type worm gear screw jacks (high precision and high efficiency) are mostly selected for the jacks, and trapezoidal screw type (stronger self-locking performance) can be selected for some heavy-duty scenarios.

- Synchronous control unit: It includes a PLC/motion controller, position sensors (encoder/grating ruler) and synchronous communication module, which collects the lifting position and speed signals of each jack in real time, and compensates the errors of each axis through electronic cam, interpolation algorithm or bus synchronization protocol (such as EtherCAT, Profinet) to ensure the lifting synchronization of multiple platforms/multi-support points of a single platform (the conventional synchronization precision can reach ±0.1~0.5mm, and the high-precision solution can reach ±0.05mm).

- Lifting platform and auxiliary mechanism: The platform is welded/spliced with steel structure/aluminum alloy profiles to ensure rigidity and uniform load bearing; it is equipped with guide mechanisms such as linear guide rails and guide pillar bushings to prevent deflection and jamming of the platform during lifting; auxiliary support beams are added in heavy-duty scenarios to disperse the load pressure of the jacks and avoid overload of a single jack.

- Auxiliary protection/limit: It includes mechanical limit (upper/lower limit), electrical limit (proximity switch), overload protection (torque sensor/current detection), and dust covers and protective covers are added in some scenarios to adapt to the dust and oil pollution environment of industrial sites.

Core structural characteristics: High modularity, the number of jacks can be flexibly increased or decreased according to the platform size and load requirements; no auxiliary facilities such as hydraulic pipelines and pump stations, compact layout, and convenient on-site installation/commissioning.

II. Core Advantages of the Servo-driven Worm Gear Screw Jack Multi-Platform Synchronous Lifting Platform

Relying on electromechanical transmission + precise servo control + mechanical characteristics of worm gears, compared with the traditional lifting platform driven by ordinary motors, its advantages focus on synchronization, precision, stability and other aspects, and it also has the general advantages of electromechanical equipment, as follows:

- High multi-platform synchronization precision and accurate positioning: The closed-loop control of the servo system + synchronous algorithm compensation can effectively eliminate the tiny errors in the processing and installation of worm gears, realize the speed synchronization and position synchronization of multiple platforms, and avoid platform tilting and workpiece offset; the lifting positioning precision can reach ±0.05~0.2mm, and the repeated positioning precision is higher, suitable for high-precision assembly, testing and other industrial scenarios.

- Wide speed regulation range, stable operation, and soft start and stop: The servo motor can realize stepless speed regulation from 0 to rated speed. Combined with the low-speed and high-torque transmission characteristics of worm gears, the lifting speed of the platform can be flexibly adjusted according to process requirements (such as low-speed precise positioning and medium-speed rapid conveying); no impact or throttling loss of the hydraulic system, no jitter during start and stop, which can effectively protect the workpieces/equipment on the platform.

- Good mechanical self-locking performance and high static stability: The worm gear transmission itself has self-locking characteristics (when the worm lead angle is less than the equivalent friction angle). The lifting platform can stay in place after power failure without additional braking devices; combined with the brake function of the servo motor, it has double anti-falling protection, suitable for high-altitude operation, workpiece static positioning scenarios, with higher safety.

- Modular design, strong adaptability and easy expansion: Worm gear screw jacks are standardized components, and the quantity and specifications can be flexibly matched according to the platform size, load weight (the load of a single jack can reach several tons) and lifting stroke; in multi-platform solutions, workstations/platforms can be added through the control system without large-scale equipment transformation, adapting to the flexible upgrading of production lines.

- Low energy consumption and low operating cost: Electric energy is only consumed during lifting actions, and no energy is consumed during static standby (the hydraulic system requires the pump station to run continuously for pressure maintaining); the high-efficiency characteristic of the servo motor (efficiency up to more than 90%) combined with the mechanical transmission of worm gears results in much lower energy consumption than the hydraulic type, which can greatly reduce the electricity cost in long-term operation.

- Simple maintenance, low failure rate and friendly on-site environment: No hydraulic oil, no pipelines and no seals, avoiding the common oil leakage and seepage problems of the hydraulic system, and no need to regularly replace hydraulic oil and maintain seals; the core wearing parts are worm gears and lead screws with a long service life (more than 10,000 hours in conventional industrial scenarios), and maintenance only requires regular greasing, suitable for workshops with high cleanliness requirements (such as electronics, food, precision assembly).

- Fast response speed and strong control flexibility: The electrical signal response of the servo system is at the millisecond level, which can quickly realize the instruction switching of lifting, lowering and stopping. Combined with the PLC/motion controller, it can realize the linkage and program control of multiple workstations, and is easy to connect with the automation system of industrial production lines (such as robots, conveyors) to realize the unmanned operation of the whole line.

III. Full-Dimensional Comparison Between Servo Worm Gear Synchronous Lifting Platform and Hydraulic Lifting Platform

The hydraulic lifting platform realizes lifting by the pressure transmission of hydraulic oil, which is the mainstream solution for traditional heavy-duty lifting. Compared with the servo worm gear type, the two have significant differences in transmission principle, performance, use cost, scenario adaptation and other aspects. The following is a core comparison table to clearly present the advantages and disadvantages:

| Comparison Dimension | Servo-driven Worm Gear Screw Jack Multi-Platform Synchronous Lifting Platform | Hydraulic Lifting Platform |

|---|---|---|

| Core Transmission Principle | Electromechanical transmission: the servo motor + worm gear converts rotary motion into linear motion, with electronic synchronous control | Hydraulic transmission: the pump station provides oil pressure, the hydraulic cylinder executes, and synchronization is realized through throttle/divider valves |

| Multi-platform Synchronization Precision | High, ±0.1~0.5mm (±0.05mm for high-precision type), no cumulative error with closed-loop compensation | Low, ±1~3mm, the divider valve is easily affected by oil pressure and temperature, with cumulative error |

| Positioning/Repeated Positioning Precision | High, ±0.05~0.2mm, servo closed-loop control | Low, ±0.5~1mm, oil pressure fluctuation easily causes positioning deviation |

| Speed Regulation Characteristic | Stepless speed regulation, wide range, precise control of speed and torque | Speed regulation depends on throttle valves, with energy loss and easy crawling at low speed |

| Static Stability/Self-locking Performance | Excellent, mechanical self-locking of worm gear + servo brake, position maintenance without drift after power failure | General, requires continuous pressure maintaining by the pump station, easy to drift due to internal leakage after power failure, additional hydraulic lock is needed |

| Energy Consumption Performance | Low, power consumption only during operation, zero energy consumption in standby, efficiency over 90% | High, the pump station runs 24 hours a day, large throttling loss, efficiency only about 60% |

| Maintenance Difficulty/Cost | Low, no oil leakage, only regular greasing, few wearing parts | High, regular replacement of hydraulic oil and seals is required, pipelines are prone to oil leakage, and maintenance is cumbersome |

| On-site Environment Adaptation | Excellent, no oil pollution, high cleanliness, suitable for electronics, food, precision assembly | Poor, prone to oil leakage and seepage, polluting the workshop, supporting oil pollution treatment facilities are needed |

| Structural Layout | Compact, modular, no pump station/pipelines, small floor space, convenient installation | Complex, separate layout of pump station and pipelines is required, large floor space, cumbersome installation and commissioning |

| Response Speed | Fast, millisecond-level response of electrical signals, no delay in instruction switching | Slow, oil pressure establishment takes time, with lag in response |

| Heavy-load Capacity | Medium and heavy load: several tons for a single jack, hundreds of tons can be met by multi-jack parallel connection | Ultra-heavy load: hydraulic cylinders can easily achieve bearing of hundreds/thousands of tons |

| Operation Noise | Low, about 50~60dB, stable mechanical transmission without impact | High, about 70~80dB, high noise from pump station motor + hydraulic impact |

| Later Transformation/Expansion | Easy, adding jacks/platforms only requires debugging the control system | Difficult, expansion requires adding hydraulic cylinders, pipelines and pump stations, and redesigning the oil circuit |

Summary of Core Differences

- Servo worm gear type: Excels in precision, synchronization, energy consumption, maintenance and cleanliness, suitable for medium and heavy load, high synchronization, high precision and clean industrial scenarios, such as multi-station assembly lines, precision testing platforms, electronic component conveying, food processing lifting, etc.;

- Hydraulic type: Excels in ultra-heavy load capacity, suitable for scenarios with no precision/synchronization requirements and no on-site cleanliness requirements (such as large cargo lifting, large equipment installation), with stronger load capacity and lower initial equipment cost.

IV. Supplementary: Minor Limitations of the Servo Worm Gear Screw Jack Synchronous Lifting Platform

Compared with the hydraulic type, it has certain limitations in ultra-heavy load scenarios: although the worm gear transmission can improve the load capacity through multi-jack parallel connection, the load of a single jack is limited by the mechanical structure. Compared with the large-bore ultra-heavy load of hydraulic cylinders, the equipment volume will be larger and the cost will increase slightly in extreme heavy load scenarios such as thousands of tons; in addition, in the extreme environment of ultra-low/ultra-high temperature, the grease of worm gears is prone to failure, requiring supporting special high-temperature/low-temperature resistant lubricating materials, while the hydraulic type can adapt to a wider temperature range by replacing hydraulic oil.

V. Scenario Selection Suggestions

- For the requirements of industrial automation production lines, precision assembly/testing, multi-station synchronous lifting and clean production with a load of within hundreds of tons (medium and heavy load), the servo-driven worm gear screw jack multi-platform synchronous lifting platform is the first choice, which can balance precision, efficiency and operating cost;

- For scenarios with pure ultra-heavy load, no precision/synchronization requirements and no on-site cleanliness requirements (such as heavy cargo lifting, large equipment installation), the hydraulic lifting platform can be selected, which has stronger load capacity and lower initial equipment cost.