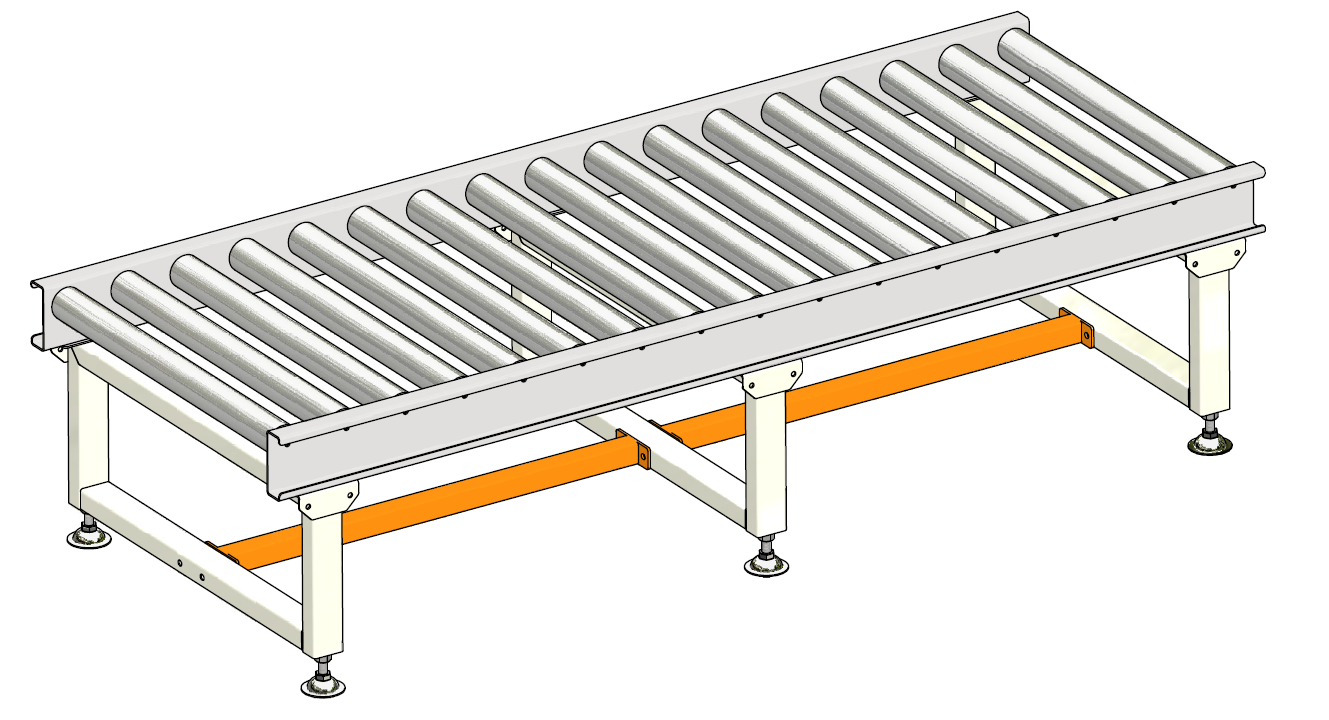

Roller conveyor line for packaging

Roller conveyors are essential for packaging lines, handling cartons, pallets and bags in processes like sealing, labeling and palletizing, boasting stable conveyance and flexible equipment docking. Modular in structure, they include frames, rollers, auxiliaries and a power system (for powered models), with variants by power (non-powered/powered), layout and load capacity. Key parameters cover roller specs, conveyor dimensions and motor power, tailored to light/medium/heavy loads. Critical for use: precise equipment matching, anti-slip designs for flexible packages and material customization for food/humid scenarios.

Technical Analysis of Roller Conveyors for Packaging Applications

Roller conveyors are the core conveying equipment in packaging production lines, suitable for the continuous/intermittent transportation of various packaged items such as cartons, plastic crates, pallets and packaging bags. They are widely used in packaging processes including sorting, palletizing, carton sealing, labeling and case packing. Their core features are stable conveyance, strong load adaptability, flexible docking with packaging equipment and easy maintenance. This document elaborates on four key aspects: structural composition, common types, core technical parameters and selection parameter table, all tailored to the actual application scenarios of the packaging industry.

I. Core Structural Composition

Roller conveyors for packaging adopt a modular design, with all components independently adapted to the requirements of packaging processes. The core structure of non-powered and powered models is basically the same, with differences only in the power system. The structure is divided into four major parts: base frame, roller assembly, auxiliary functional components and power/transmission system (exclusive to powered models), as detailed below:

- Base FrameThe core load-bearing structure that directly determines the load capacity, stability and installation adaptability of the conveyor. The commonly used materials in the packaging industry are cold-rolled steel with spray coating (for conventional working conditions, low cost) and 304 stainless steel (for food packaging, humid/oily packaging environments such as fresh food and daily chemical packaging). Frame types include square tube welded type (for heavy packaged items such as pallets and large cartons) and aluminum profile assembled type (for light packaged items such as small packaging boxes and bags, featuring modular splicing and easy line modification).

- Roller AssemblyThe components in direct contact with packaged items, with a single roller as the core unit. The mainstream rollers for packaging applications are seamless steel pipe rollers (high load capacity, suitable for cartons/pallets), plastic rollers (lightweight, suitable for small packaged items, scratch-resistant for packaging surfaces) and rubber-coated rollers (silicone/rubber coating, anti-slip/shock-absorbing, suitable for slippery packaged items such as film-coated cartons and plastic bags). Both ends of the roller are equipped with bearing blocks (stamped/die-cast) to ensure smooth rotation and reduce conveyance resistance of packaged items.

- Auxiliary Functional ComponentsKey accessories adapted to packaging processes, the core of customization for packaging production lines, widely used in the packaging industry:

- Side guards/rails: Prevent deviation of packaged items, suitable for processes requiring positioning accuracy such as labeling and carton sealing, with height adjustable according to the size of packaged items;

- Lifting and transfer mechanism: Realize direction switching, diverging and converging of packaged items, suitable for commutation processes before sorting and palletizing;

- Positioning baffle: Achieve precise positioning and stopping of packaged items, suitable for stationary operations such as case packing and labeling;

- Anti-slip strips/support strips: For light flexible packaging items (such as packaging bags), prevent them from falling into roller gaps and ensure smooth conveyance;

- Adjustable feet/pads: Adjust the level of the conveyor, adapt to uneven workshop floors, and reduce vibration and noise simultaneously.

- Power/Transmission System (Exclusive to Powered Models)Provides power for rollers to ensure continuous conveyance of packaged items. Powered models for packaging are designed with the core requirement of low speed and high torque to avoid slipping/toppling of packaged items:

- Power source: Mainstream options are gear motors (fixed speed, suitable for conventional continuous conveyance) and variable frequency gear motors (speed adjustable, suitable for intermittent conveyance linked with labeling/carton sealing machines), with power matched according to conveyor length and load capacity;

- Transmission mode: Commonly used in the packaging industry are chain and sprocket transmission (single/double row, high load capacity, easy maintenance, suitable for medium and heavy packaged items) and O-belt transmission (low noise, stable operation, suitable for light packaged items such as small packaging boxes). Timing belt transmission is mostly used for high-precision positioning conveyance (such as high-speed labeling).

II. Common Types in the Packaging Industry (Classified by Core Attributes)

The classification of roller conveyors for packaging is designed around characteristics of packaged items, process requirements and installation scenarios. Non-powered models focus on manual auxiliary conveyance, while powered models focus on automated linkage. The following are the most commonly used types and their application scenarios, covering most packaging processes:

(I) Classification by Power Mode (Core classification, applicable to all packaging scenarios)

- Non-powered Roller Conveyor

- Principle: Realize conveyance by the self-gravity of packaged items (inclined layout) or manual pushing force (horizontal layout);

- Features: Simple structure, low cost, no maintenance difficulty, flexible modular splicing;

- Packaging scenarios: Manual carton sealing, manual labeling, manual case packing, temporary storage of packaged items in warehouses, short-distance conveyance in small packaging production lines.

- Powered Roller Conveyor

- Principle: The motor drives the transmission system to drive roller rotation and realize automatic conveyance of packaged items;

- Features: High degree of automation, linkable with packaging equipment (carton sealers, labeling machines, palletizers, case packers), supporting fixed speed/speed adjustment/intermittent operation;

- Packaging scenarios: Fully automated packaging production lines, high-speed sorting lines, long-distance conveyance of large cartons/pallets, linked conveyance for labeling/carton sealing/palletizing.

(II) Classification by Layout (Adapted to workshop layout and packaging process flow)

- Horizontal Roller ConveyorThe most commonly used type with a horizontal conveying surface, suitable for linear conveyance of most packaged items, such as connecting conveyance before and after labeling machines and carton sealers.

- Inclined Roller Conveyor (Uphill/Downhill)The conveying surface is at a certain inclination angle. Downhill is mostly non-powered (utilizing gravity), and uphill is powered (motor-driven). It is suitable for connecting high and low platforms in workshops, transporting packaged items up and down floors in warehouses, and material sliding conveyance in case packing processes. The inclination angle is generally ≤15° (to prevent toppling/slipping of packaged items).

- Curved Roller ConveyorDivided into 90°/180° curves, with tapered rollers/universal rollers to ensure stable conveyance at curves without dead angles. Suitable for direction switching in packaging production lines and corner conveyance in workshop layout, such as diverging curves in sorting lines and commutation conveyance before palletizing.

- Diverging/Converging Roller ConveyorEquipped with lifting and transfer mechanisms and guiding devices to realize diverging (one line to multiple lines) or converging (multiple lines to one line) of packaged items in multi-channel. Suitable for sorting of packaged items and converging conveyance after multi-station case packing, such as sorting and diverging in e-commerce packaging and multi-line converging palletizing in food packaging.

(III) Classification by Load Capacity (Matching the weight of packaged items to avoid over-design/insufficient load capacity)

- Light-duty Roller Conveyor

- Single roller load capacity: ≤50kg;

- Adapted packaged items: Small packaging boxes (such as cosmetics, stationery, snacks), small plastic crates, light packaging bags;

- Scenarios: Small-scale labeling, small package case packing, e-commerce small package conveyance.

- Medium-duty Roller Conveyor

- Single roller load capacity: 50-200kg;

- Adapted packaged items: Conventional cartons (such as whole cartons of home appliances, daily chemicals, food), medium plastic crates, woven bags (such as rice, flour);

- Scenarios: Mainstream packaging production lines (carton sealing, labeling, case packing), conventional sorting and conveyance, the most universal type in the packaging industry.

- Heavy-duty Roller Conveyor

- Single roller load capacity: ≥200kg;

- Adapted packaged items: Large cartons (such as packaging for refrigerators, washing machines), wooden/plastic palletized packaged items, heavy plastic crates;

- Scenarios: Conveyance before palletizing for heavy product packaging, warehousing and transportation of palletized packaged items, packaging conveyance of large equipment.

(IV) Classification by Special Functions (Adapted to personalized requirements of packaging processes)

- Rubber-coated Roller Conveyor: Rollers with silicone/rubber coating, anti-slip, shock-absorbing and scratch-resistant for packaging surfaces, suitable for conveyance of film-coated cartons, color boxes and slippery plastic crates, such as labeling conveyance for gift packaging and cosmetic packaging.

- Universal Roller Conveyor: Universal ball rollers allow packaged items to move in any direction, suitable for positioning, steering and sorting of packaged items, such as material placement in manual case packing and positioning of packaged items before labeling.

- Lifting Roller Conveyor: Equipped with a lifting mechanism to realize lifting and stopping of packaged items, suitable for docking with other conveying equipment (such as belt conveyors) and precise positioning operation for labeling/carton sealing.

III. Core Technical Parameters (Exclusive to the packaging industry, core basis for selection)

The parameters of roller conveyors for packaging directly determine the adaptability to packaged items, packaging equipment and workshop layout. All parameters are designed around packaging processes, mainly divided into three categories: core roller parameters, overall conveyor parameters and power parameters. Non-powered models have no power parameters:

(I) Core Roller Parameters (Direct contact with packaged items, the most critical)

- Roller diameter: Mainstream specifications in the packaging industry are φ38mm, φ50mm, φ60mm, φ76mm, φ89mm; φ38/50mm for light-duty, φ60/76mm for medium-duty, φ89mm for heavy-duty;

- Roller length: The effective length of a single roller must be 50-100mm longer than the maximum width of the packaged item to prevent deviation, mainstream length ranges from 300-2000mm, customizable;

- Roller center distance: The supporting surface of the packaged item must contact at least 3 rollers to prevent sagging/inclination; 30-50mm for light packaged items, 60-100mm for medium-duty, 120-200mm for heavy-duty; the distance for flexible packaging items (such as packaging bags) must be reduced to 30-50mm;

- Roller material: Cold-rolled steel (conventional), 304 stainless steel (food/humid packaging), plastic (lightweight and scratch-resistant), rubber coating (anti-slip/shock-absorbing);

- Roller wall thickness: Mainstream specifications for cold-rolled steel rollers are 1.2mm, 1.5mm, 2.0mm, 3.0mm; 1.2/1.5mm for light-duty, 1.5/2.0mm for medium-duty, 2.0/3.0mm for heavy-duty.

(II) Overall Conveyor Parameters

- Conveying width: Effective conveying width, adapted to the maximum width of packaged items, mainstream range from 300-1800mm, customizable, matched with roller length;

- Conveying length: Modular splicing, 1-6m per section, infinitely spliceable, designed according to workshop layout and production line length;

- Conveying speed: Core parameter of powered models, mainstream range in the packaging industry is 0.5-3m/s, variable frequency speed adjustable; when linked with labeling/carton sealing machines, the speed must be synchronized with the equipment, generally ≤1.5m/s;

- Rated load capacity: Divided into linear load capacity (per meter) and overall load capacity, ≤50kg/m for light-duty, 50-200kg/m for medium-duty, ≥200kg/m for heavy-duty;

- Layout inclination angle: Angle for inclined conveyance, generally ≤15°, rubber-coated anti-slip rollers can be appropriately increased to 20° to prevent toppling/slipping of packaged items;

- Frame material: Cold-rolled steel with spray coating (conventional), 304 stainless steel (food/humid/oily), industrial aluminum profiles (lightweight and modular);

- Installation height: Universal 750-850mm in the packaging industry (adapted to manual operation), must be consistent with the height of packaging equipment when docking, adjustable ±50mm through adjustable feet.

(III) Power Parameters (Exclusive to Powered Models)

- Motor type: Gear motor (fixed speed), variable frequency gear motor (speed adjustable), stainless steel motor optional for food packaging;

- Motor power: Matched according to conveyor length and load capacity, 0.25-0.75kW for 1-4m per section, 0.75-1.5kW for 4-8m, 1.5-3.0kW for more than 8m, increased on demand for heavy-duty conveyors;

- Transmission mode: Chain and sprocket (medium and heavy-duty), O-belt (lightweight and low noise), timing belt (high precision);

- Voltage: Industrial universal 380V/50Hz (three-phase), 220V/50Hz (single-phase) customizable for small light-duty models.

IV. Selection Parameter Table of Roller Conveyors for Packaging (Direct application, covering 90% of packaging scenarios)

Combined with the most commonly used light-duty, medium-duty and heavy-duty classifications in the packaging industry, a standardized selection parameter table is compiled, including adapted packaged items, core parameters and applicable processes, which can be directly used as the selection basis. Special scenarios (such as food, explosion-proof) can be customized and adjusted on this basis:

| Type | Adapted Packaged Items | Single Roller Load | Linear Load (per meter) | Roller Diameter | Roller Center Distance | Frame Material | Power Configuration (Powered Model) | Applicable Packaging Processes |

|---|---|---|---|---|---|---|---|---|

| Light-duty | Small boxes, small plastic crates, light bags | ≤50kg | ≤50kg | φ38/50mm | 30-50mm | Aluminum profile/cold-rolled steel with spray coating | 0.25-0.5kW variable frequency gear motor + O-belt transmission | Small-scale labeling, small package case packing, e-commerce small package sorting, manual carton sealing |

| Medium-duty | Conventional cartons, medium plastic crates, woven bags | 50-200kg | 50-200kg | φ60/76mm | 60-100mm | Cold-rolled steel with spray coating/304 stainless steel | 0.5-1.5kW variable frequency gear motor + chain and sprocket transmission | Mainstream carton sealing, labeling, case packing, automatic sorting, production line linked conveyance |

| Heavy-duty | Large cartons, palletized items, heavy plastic crates | ≥200kg | ≥200kg | φ89mm | 120-200mm | Heavy-wall cold-rolled steel with spray coating | ≥1.5kW variable frequency gear motor + double-row chain and sprocket transmission | Heavy product packaging, pre-palletizing conveyance, palletized item transportation, large equipment packaging |

Supplementary Selection for Special Scenarios (Food/Humid/Anti-slip)

| Special Scenario | Core Customized Parameters | Adapted Packaged Items |

|---|---|---|

| Food Packaging | 304 stainless steel frame + stainless steel rollers + waterproof motor | Food cartons/plastic crates, fresh food packaging items |

| Humid/Oily Environment | 304 stainless steel material + sealed bearing blocks | Daily chemical packaging items, hardware packaging items |

| Slippery Packaged Items | Silicone/rubber-coated rollers + inclination angle ≤10° | Film-coated cartons, color boxes, plastic crates |

V. Key Application Notes for Roller Conveyors for Packaging

- When docking with packaging equipment (carton sealers, labeling machines, palletizers), the conveying speed, installation height and conveying width must be precisely matched with the equipment, and linkage interfaces must be reserved;

- For flexible packaging items (such as packaging bags and flexible plastic crates), small center distance rollers must be selected, and support strips/anti-slip strips added to prevent falling into roller gaps;

- For high-speed packaging processes (such as high-speed labeling), variable frequency speed adjustment + timing belt transmission must be adopted to ensure stable conveyance without jitter and improve packaging accuracy;

- The food packaging industry must select full 304 stainless steel material with waterproof treatment to comply with food hygiene standards;

- If the workshop has explosion-proof requirements (such as chemical product packaging), explosion-proof gear motors + explosion-proof electrical accessories must be selected to meet explosion-proof grade requirements;

- During modular splicing, the length of a single conveyor section should not exceed 6m; overlong sections may cause asynchronous roller rotation and affect conveyance stability.