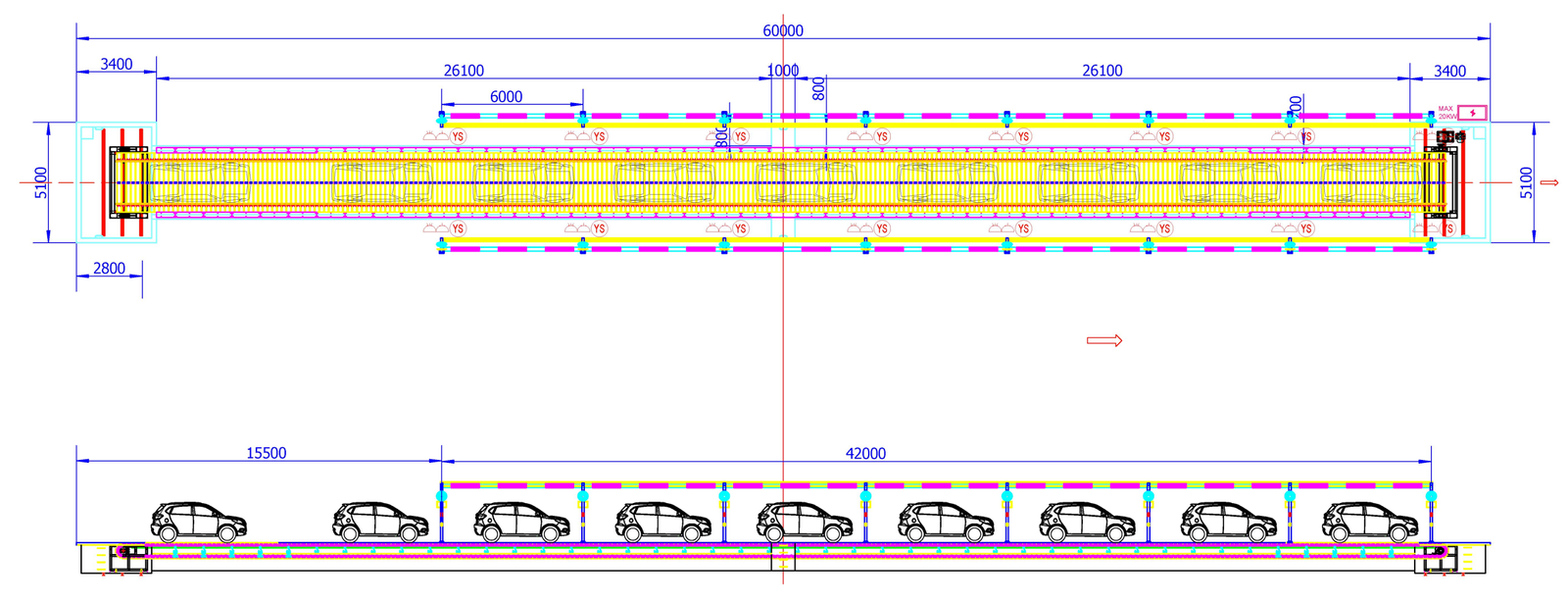

General-purpose vehicle assembly conveyor system

The buried plate chain conveyor line is a key equipment for universal automobile assembly, featuring a robust structure with drive/tensioning units, heavy-duty chains, anti-skid platform plates and an intelligent electric control system. It offers adjustable speed (2-6m/min), high load capacity (2T per workstation) and stable, low-noise operation. Its underground design saves floor space, and it integrates well with automated systems, widely applied in auto interior assembly, adjustment and final inspection lines to boost assembly efficiency and automation.

Buried Plate Chain Conveyor Line for Universal Automobile Assembly

The buried plate chain conveyor line is a commonly used conveying equipment in automobile assembly production lines. It features stable operation and high load-bearing capacity, which can effectively improve the production efficiency and automation level of automobile assembly. Here is a detailed introduction to the buried plate chain conveyor line for universal automobile assembly:

Structural Composition

- Drive Unit: It usually adopts a continuous conveying operation mode. The sprocket is generally made of ZG45 material with tooth surface heat treatment to HRC40-42, and the base is a profile welded part. It is equipped with a standard bush roller chain, as well as overload thermal protection and mechanical shear pin protection devices.

- Tensioning Unit: A weight tensioning unit is mostly adopted, with a coaxial double-sprocket structure, consisting of sliding bearings, a tensioning shaft, sprockets, a tensioning lead screw and a bracket. The shaft, sprocket, lead screw and other components are generally made of 45# steel.

- Chain: A single-lug plate structure roller chain is usually selected, with the pitch determined according to actual requirements (e.g., 250mm) and the chain plate thickness of about 8mm. The shaft is quenched and tempered, and the roller surface is quenched. In addition, the roller is with a flange for left and right limit of the chain.

- Platform Plate: It is generally a flanged structure made of 6mm anti-skid checkered plate to ensure its load-bearing capacity. For platform plates with a large span, a set of support wheels is added in the middle, and the platform plate and the chain are connected by lock nuts to prevent loosening.

- Rail Frame: It adopts a channel steel welded structure with adjustable height for easy installation. The upper track uses light rail, which is made of 50Q and fixed on the rail frame by pressure plates; the lower track is formed by welding angle steel with the rail frame.

- Electronic Control System: It controls the operation, speed regulation and fault detection of the conveyor line to ensure the stable operation of the conveyor line according to the set program.

Technical Parameters

- Conveying Speed: The running speed is generally adjustable between 2-6m/min, and frequency conversion speed regulation can be carried out according to the requirements of automobile assembly processes.

- Workstation Spacing: For example, the workstation spacing of an automobile final assembly line is 6250mm, which can be determined according to the vehicle model size and the operating space requirements for assembly.

- Load-bearing Capacity: Heavy-duty plate chain conveyors are commonly used in automobile manufacturing, with a workstation load-bearing capacity of up to about 2 tons, which can meet the weight requirements for the conveying of automobile parts and complete vehicle assembly.

- Plate Chain Width: It is determined according to the size and conveying capacity of the conveyed items. For example, the plate width of the wide plate line used for automobile assembly can reach 3000mm.

Characteristics and Advantages

- Space-saving: The buried design conceals the conveyor line under the ground, which does not occupy ground space, is conducive to the spatial layout and personnel operation of the workshop, and makes the workshop more neat and orderly.

- Stable Operation: The plate chain conveyor line runs stably without obvious crawling, with smooth mechanical meshing, no noise and jamming, which can ensure the stability and safety of automobile parts during conveying.

- High Load-bearing Capacity: It can bear large loads, meet the conveying requirements of automobiles and their parts, and is suitable for the assembly and conveying of heavy components such as engines and vehicle bodies.

- High Automation Level: It can be integrated with other automated equipment and systems to realize automated flow operation in the automobile assembly process, improve production efficiency and reduce manual intervention.

Application Scenarios

- Automobile Interior Assembly Line: Used for the assembly and conveying of automobile interior parts, such as the transfer of seats, instrument panels, door interiors and other components, to achieve seamless connection between various assembly workstations.

- Automobile Adjustment Line: After the completion of automobile assembly, it is used to convey vehicles to adjustment workstations for the adjustment and detection of various performances.

- Automobile Final Assembly Line and Inspection Line: Convey the assembled automobiles to the final inspection workstations for a comprehensive quality inspection to ensure that the vehicles meet the ex-factory standards.