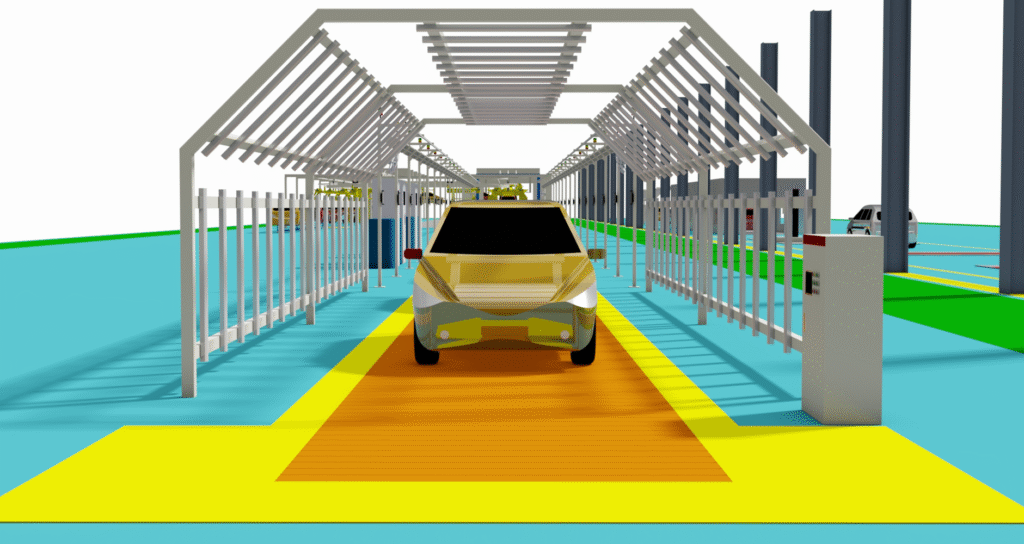

Drawing of Heavy – duty Underground Plate Chain Conveyor

Heavy underground plate chain conveyor drawings, used for learning, manufacturing, assembling and installing heavy conveyors.

Heavy-duty underground plate chain conveyor is widely used in manufacturing factories. It can effectively improve production efficiency, reduce labor intensity and ensure the smooth production process. Here are some specific application scenarios in different manufacturing factories:

Mechanical manufacturing factory

- Large component assembly: In the assembly workshop of a mechanical manufacturing factory, heavy-duty underground plate chain conveyors can be used to transport large mechanical components, such as engine blocks and large gearboxes. These components are usually large in volume and heavy in weight. With the help of underground plate chain conveyors, they can be smoothly transported from the processing area to the assembly area to achieve automated assembly and improve assembly efficiency.

- Material handling: In the factory, underground plate chain conveyors can be used to handle various raw materials and semi-finished products, such as steel and cast iron parts. These materials often need to be transported between different processing areas. Underground plate chain conveyors can realize efficient and stable material handling, reducing the labor intensity and time cost of manual handling.

Automobile manufacturing factory

- Body assembly line: In the body assembly workshop of an automobile manufacturing factory, heavy-duty underground plate chain conveyors can be used to transport the body frame and large components of automobiles. These components need to be accurately positioned and assembled at different assembly stations. Underground plate chain conveyors can achieve high-precision conveying and positioning to ensure assembly quality.

- Connection between parts warehouse and production line: Underground plate chain conveyors can connect the parts warehouse with the production line in an automobile manufacturing factory to achieve automated replenishment of parts. Through the conveyor, parts can be automatically transported to various stations on the production line according to the production plan, improving production efficiency and reducing the accumulation of parts inventory.

Electronics manufacturing factory

- Large electronic equipment assembly: In an electronics manufacturing factory, some large electronic equipment, such as server cabinets and large monitors, need heavy-duty underground plate chain conveyors for assembly. These devices are usually large in volume, heavy in weight, and have high requirements for assembly accuracy. Underground plate chain conveyors can achieve smooth and precise conveying to meet the assembly requirements.

- Raw material and finished product transportation: Underground plate chain conveyors can also be used to transport raw materials and finished products in an electronics manufacturing factory. For example, transporting large circuit boards and electronic components. These materials need to be transported between different production stages. Underground plate chain conveyors can realize efficient and stable transportation, reducing the risk of material damage during transportation.

Furniture manufacturing factory

- Large furniture component handling: In a furniture manufacturing factory, heavy-duty underground plate chain conveyors can be used to handle large furniture components, such as sofa frames and bed frames. These components are usually large in volume and heavy in weight. With the help of underground plate chain conveyors, they can be smoothly transported from the processing area to the assembly area, improving assembly efficiency.

- Finished furniture transportation: Underground plate chain conveyors can also be used to transport finished furniture in a furniture manufacturing factory, transporting finished furniture from the production workshop to the packaging area or warehouse. This method can reduce the labor intensity of manual handling, improve transportation efficiency, and avoid damage to furniture during transportation.

Metal processing manufacturing factory

- Large metal sheet and profile transportation: In a metal processing manufacturing factory, heavy-duty underground plate chain conveyors can be used to transport large metal sheets and profiles. These materials are usually heavy and need to be transported between different processing equipment. Underground plate chain conveyors can realize efficient and stable transportation, reducing the labor intensity and time cost of manual handling.

- Transportation of metal products after heat treatment: For some metal products that have undergone heat treatment, such as large shaft parts after quenching, underground plate chain conveyors can operate stably in high-temperature environments. They can transport these parts from the heat treatment furnace to the subsequent processing or inspection area to ensure the continuity of the production process.

The drawings are for sale

The drawings are available in 3D STP format and 2D CAD drawings, which include chain dimensions, transmission devices, sheet metal parts, and structural steel components. During the manufacturing process, laser cutting machines, press brakes, and welding machines will be utilized. The general reference drawings are priced at 3000 USD. Technical support is an additional 2000 USD. If customization is required, there will be an extra charge of 2000 USD. Professional engineers will provide specialized services.