How to Choose the Right Assembly-Line Strapping Machines

Assembly-line strapping machines are grouped by automation, frame style, material and direction; choices range from side-seal and sword types for pallets to press types for fluffy bales. PET cord delivers steel-like strength at lower weight. Match speed and tension to carton size and line takt; servo length cuts strap use 5-8 %. Low-table or horizontal models integrate straight into roller conveyors, while vision and network ports enable unmanned, traceable operation.

I. Five-Dimension Classification of Assembly-Line Strapping Machines

| Dimension | Common Type | One-sentence description |

|---|---|---|

| Automation | Manual, semi-auto, fully-auto, unmanned cell | Unmanned = auto strap feed + auto indexing + data interface to MES |

| Frame style | High-table, low-table, side-seal, horizontal, sword, press, rotary ring | Low-table for pallet line; side-seal against liquid drip; sword for pallet strapping |

| Strap material | PP, PET cord, steel, paper, stretch film | PET ≈ 60 % of steel strength, 1/6 weight, preferred on line |

| Strap direction | Vertical, horizontal, orbital, diagonal | Horizontal = “girth” strap on pallet; orbital for tyre/coil |

| Special function | Press & de-aerate, sword through pallet, heat-seal, servo length, vision | Press saves 20-40 % volume; servo saves 5-8 % strap |

II. Typical Structure & In-line Layout

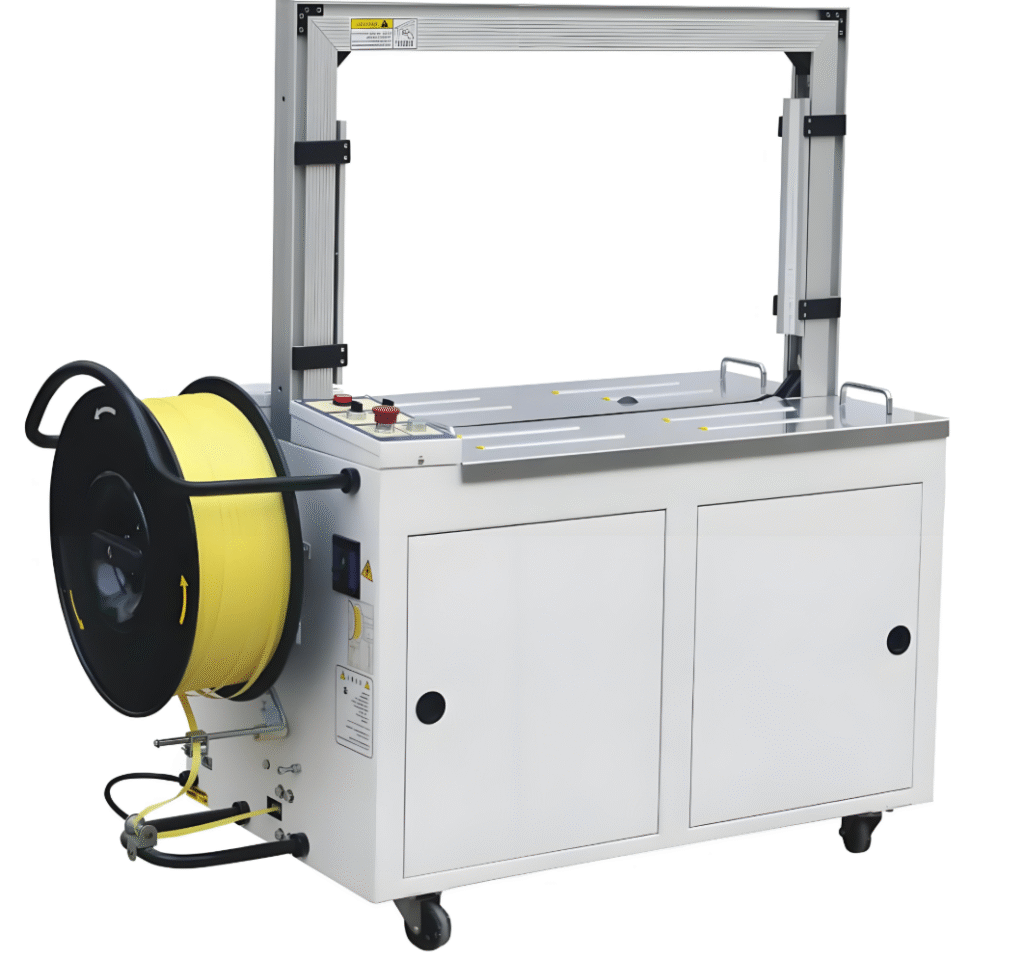

- High-table fully-auto

Driven roller → photo-eye → arch down → strap feed → heat-seal → out. - Low-table fully-auto

Table 450 mm, same height as pallet conveyor; forklift drops load, automatic cycle. - Side-seal

Arch turned 90°; strap closes from left/right; open top, no fear of liquid. - Horizontal strapping machine

Strap runs horizontally, “girth” pallet; front & rear motorised rollers insertable into conveyor. - Sword type

Sword arm extends through pallet void; pallet + load strapped together; sword width 850-1 250 mm optional. - Press type

Top cylinder 20-60 kN pre-compresses fluffy goods, then straps; height reduced 20-40 %.

III. Industry-Product-Machine Quick Match

| Industry | Typical goods | Suggested machine | Key points |

|---|---|---|---|

| Appliances | Fridge, AC outdoor | Low-table + horizontal | Pallet 1 200×1 000, choose 1 250 sword |

| Food & drink | Bottled water, carton milk | High-table / side-seal | Stainless IP54, side-seal against drip |

| Daily & e-commerce | Cosmetic carton | High-table dual arch | Servo length saves 6-8 % strap |

| Pharmaceutical | Drug carton, IV bottle | High-table fully-auto | GMP, oil-free head |

| Building materials | Tile, aluminium profile | Sword + horizontal | PET 19×1.0 mm, break force ≥ 4 000 N |

| Publishing / e-commerce | Books, small parcel | High-table semi-auto | Table 730 mm, low investment |

| Chemical fibre | Fluffy fibre bale | Press fully-auto | Air 0.4-0.6 MPa, compression 2.5:1 |

IV. Key Selection Data (Rule-of-Thumb)

| Parameter | Rule | Note |

|---|---|---|

| Arch inner | W + H < arch – 30 mm | Common 600×400 / 800×600 / 1 000×800 mm |

| Speed | Fully-auto 25-35 straps/min | Double strap = ×2 |

| Strap width | 9 / 12 / 15.5 mm (PP); 19 / 25 mm (steel) | Wider = stronger = dearer |

| Tension | 0-450 N (PP); 0-3 000 N (PET) | Home-appliance carton 200-250 N enough |

| Enclosure | Indoor IP40; food IP54; Ex d IIB T4 | Ex-proof needs pneumatic motor & anti-static strap |

| Interface | Same height as roller; 380 V + 6 bar; RS485 / MQTT | Unmanned needs network port |

V. Generic Model Quick Chart (Brand-Neutral)

| Example model | Automation | Table height | Action | Strap width | Speed | Highlights | Typical use |

|---|---|---|---|---|---|---|---|

| 101A | Auto | 730 mm | Std high-table | 9-15.5 mm | 25 /min | Economical | Carton line |

| 102A | Fully-auto | 730 mm | Motor roller + photo-eye | same | 30 /min | No hand push | E-commerce |

| 102B | Fully-auto | 450 mm | Low motor roller | same | 28 /min | Flush with pallet line | Appliance pallet |

| 103A | Fully-auto | 730 mm | Side-seal arch | same | 25 /min | Anti-drip | Sauce, dairy |

| 105A | Fully-auto | 450 mm | Horizontal orbital | 12-19 mm | 20 /min | Pallet girth | Beverage, tiles |

| 105B | Fully-auto | 450 mm | Sword through pallet | 12-19 mm | 18 /min | Pallet + load | Fibre, tiles |

| 106A | Fully-auto | 450 mm | Press + sword | 15.5-25 mm | 12 /min | Press then strap | Fibre, cotton |

| A1 | Semi-auto | 730 mm | High-table arch | 6-15 mm | 3 s/strap | Low price | Small warehouse |

VI. 5-Step Purchasing Checklist

- Measure 3 sizes: biggest carton / pallet / roller height → choose arch & head.

- Calculate takt: peak cartons ÷ straps per carton ≥ rated speed × 0.8.

- Ask strap saving: servo length vs mechanical saves 5-8 %; big annual volume pays back.

- Check support: local tech? 4-hour response?

- Test real samples: run extreme heavy / tall / odd boxes 1 h on site—better than paper specs.