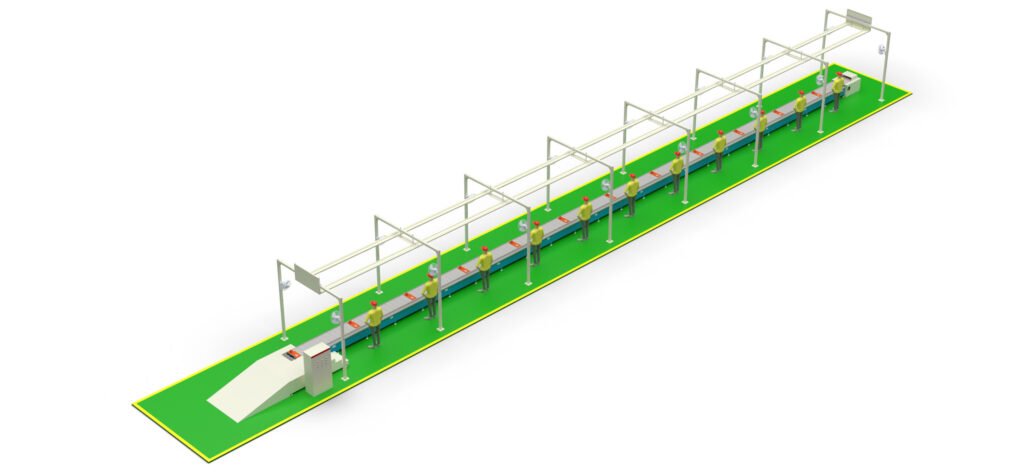

Motorcycle assembly line manufacturing drawings

General-purpose motorcycle assembly line production processing drawings.

The chain conveyor is a type of conveying equipment that uses chains as the traction and load-bearing body. It is widely used in many fields. The following is a detailed introduction to it.

Structure

- Conveying chain: It is the core part of the conveyor. Usually, special needle roller chains are used, which have high strength and wear resistance and can carry heavy materials.

- Chain plate: As the load-bearing surface, various materials can be selected, such as galvanized carbon steel or stainless steel, to meet different application environments and material characteristics.

- Drive unit: Generally, a motor reducer provides power to drive the chain movement, thereby driving the chain plate to convey materials.

- Frame: Usually made of carbon steel or aluminum alloy, it supports the structure of the entire conveyor to ensure its stable operation.

- Auxiliary devices: Such as blocking devices, lift and transfer mechanisms, etc., are used to realize the functions of stopping, releasing, and turning materials to meet different production requirements.

Working principle

- The drive unit drives the chain through the chain to drive the chain plate movement. Materials are placed on the chain plate and are conveyed to the designated position with the movement of the chain plate.

- By controlling the speed and operating time of the drive unit, the precise conveying and assembly of materials can be realized.

Features

- High load capacity: It can carry heavy materials, such as heavy mechanical parts, large household appliances, etc.

- Smooth operation: The conveying speed is accurate and stable, which can ensure precise synchronous conveying and is suitable for assembly operations on production lines.

- Strong adaptability: It can be customized according to different process requirements, such as straight type, turning type, climbing type, etc., to meet various complex production layouts.

- Easy maintenance: The equipment has a simple structure and is easy to maintain and clean, reducing maintenance costs and downtime.

- Durability: The chains and chain plates and other components have high wear resistance and corrosion resistance, and have a long service life.

Application fields

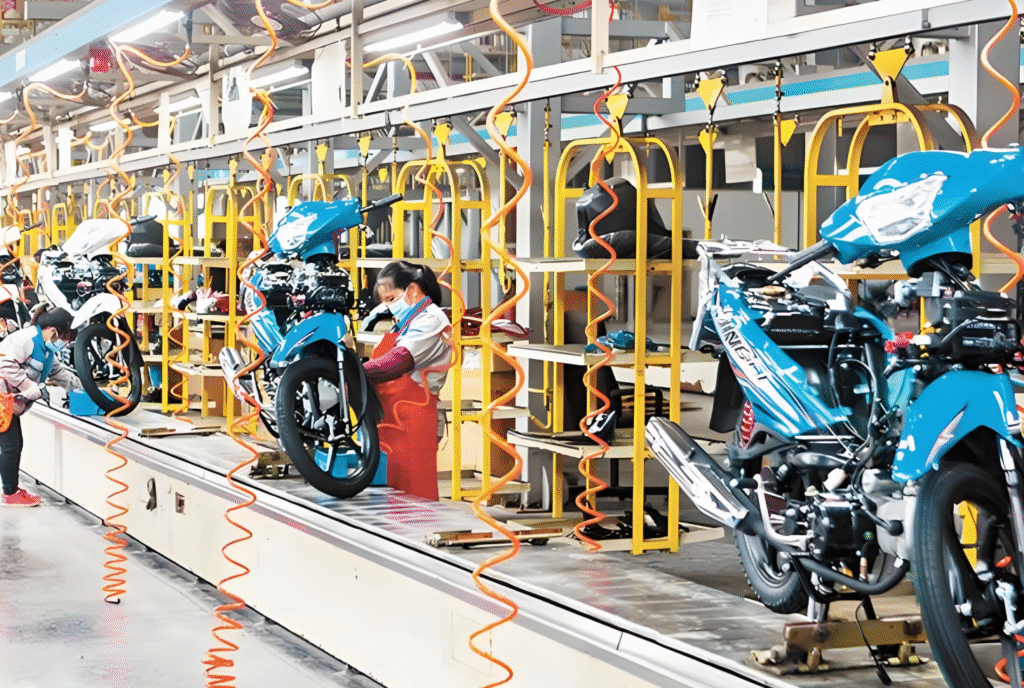

- Automobile manufacturing: It is used for the assembly and conveying of automobile parts, such as engine, transmission and other production lines.

- Household appliance industry: On the production lines of household appliances such as refrigerators, washing machines, and air conditioners, it is used for product assembly and transportation.

- Mechanical manufacturing: It is suitable for the processing and assembly process of various mechanical parts.

- Logistics and warehousing: It is used for goods conveying and warehouse management in logistics centers.

- Food and beverage: On the production lines of the food and beverage industry, it is used for product conveying and packaging.

The chain conveyor plays an important role in modern industrial production with its unique structural and performance advantages, and provides strong support for improving production efficiency and product quality.

The drawings are for sale

The drawings are available in 3D STP format and 2D CAD drawings, which include chain dimensions, transmission devices, sheet metal parts, and structural steel components. During the manufacturing process, laser cutting machines, press brakes, and welding machines will be utilized. The general reference drawings are priced at 1000 USD. Technical support is an additional 1000 USD. If customization is required, there will be an extra charge of 1000 USD. Professional engineers will provide specialized services.