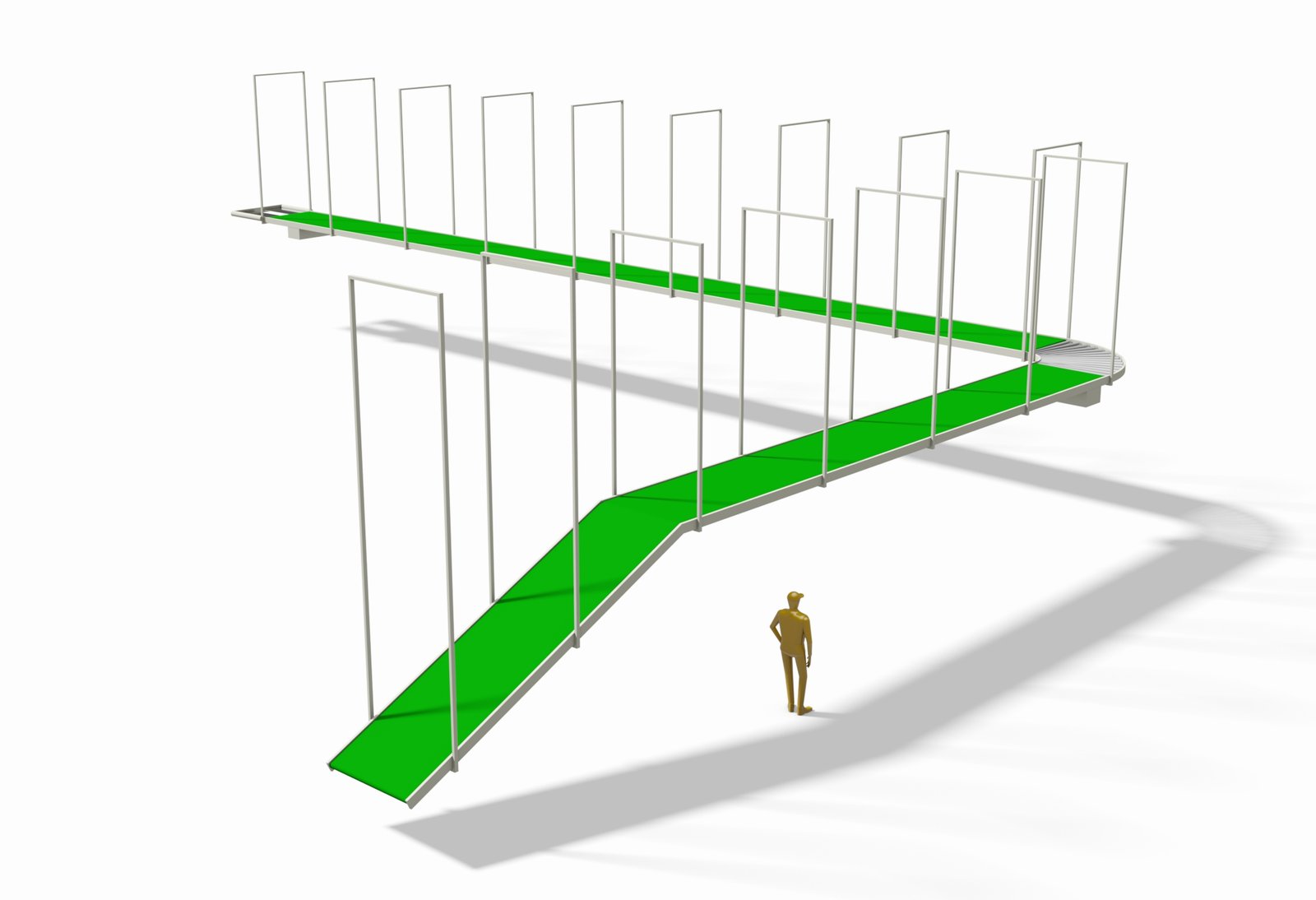

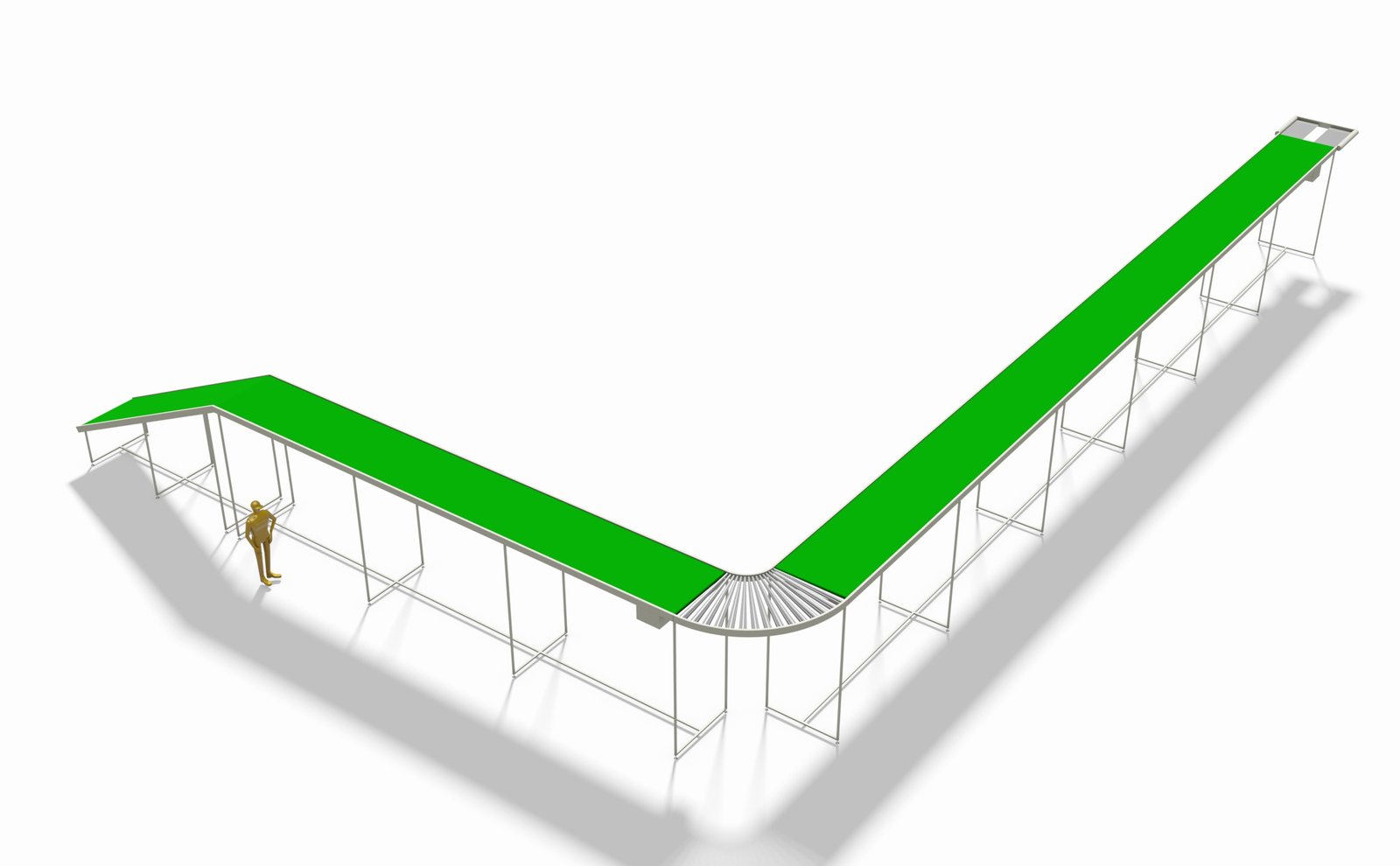

Ceiling-mounted and floor-mounted belt conveyor lines

Ceiling-mounted belt conveyors turn floor loading into roof loading and need slab-load approval, anti-vibration hangers and frequent levelling checks, giving clear floors for clean rooms or forklift traffic but raising installation and maintenance cost 15–25 %. Floor-mounted lines anchor to 500 kg/m² concrete, allow heavier loads, simpler levelling and ground-level servicing, but occupy floor space and leave bolt scars when relocated. Choose suspended only if roof capacity ≥2.5 kN/m², clearance ≥2.2 m and frequent under-traffic is required; otherwise floor type is cheaper and sturdier.

1. Key design differences

| Item | Ceiling-suspended (top-hung) | Floor-mounted |

|---|---|---|

| Civil data required | Roof-slab load report (≥2.5 kN/m² is common); pre-embedded steel beams or special hanger points for spans >6 m | Only ground uniform load check; ordinary industrial floor (500 kg/m²) is enough for light/medium duty |

| Centre-line control | Use laser plumb to transfer roof marks to floor, keep ±2 mm | Direct chalk line on floor; ±1 mm is easy |

| Take-up location | Usually gravity take-up + tail pulley hung under the line; reserve 0.8–1.2 m drop for weight travel | Screw, carriage or gravity take-up possible; space flexible, not limited by roof height |

| Anti-vibration | Damped hanger rods or spring isolators mandatory to keep start-up shock away from slab (especially >6 m/min) | Only needed if line stands on steel mezzanine; concrete floor can take direct anchor bolts |

2. Structure & load

| Item | Ceiling-suspended | Floor-mounted |

|---|---|---|

| Main frame | Twin channel or aluminium truss; ∅12–16 mm wire rope or threaded rod every 1.5–2 m; continuous beam for spans >4 m to reduce sag | 40×40, 40×80 aluminium profile or 50×50 square legs, post spacing 1–1.5 m |

| Rated load | Single hanger ≤200 kg typical; heavier loads need external floor-mounted drive platform | Single leg 500–1 000 kg common; swap to 80×80 steel legs for heavy duty |

| Deflection limit | L/500 under full load (L = hanger spacing) to avoid belt wander | L/1 000 for steel legs, easier target |

3. Erection

| Item | Ceiling-suspended | Floor-mounted |

|---|---|---|

| Setting-out sequence | 1. mark centre on slab → 2. install hanger plates → 3. level reference wire → 4. assemble truss on floor → 5. lift & level whole bay | 1. mark floor centre → 2. build first frame section → 3. add sections → 4. level complete line |

| Levelling method | Double-nut + washers on hanger rods; check every bay with level, height diff. ≤2 mm | Foot plates or jack-bolts; ≤1 mm/m, quick |

| Drive mounting | Side-mount on slab or post to isolate vibration; independent floor bracket if motor >2.2 kW | Direct on head frame, rigid fixing OK |

| Clearance | ≥0.5 m walkway under line; ≥2.2 m if forklifts cross | 0.4–0.6 m service space around frame for belt swap/clean-out |

4. Operation & maintenance

| Item | Ceiling-suspended | Floor-mounted |

|---|---|---|

| Belt wander | Very sensitive to unequal hanger length or slab vibration; re-check hanger forces every two weeks | Good rigidity, low wander; routine visual check enough |

| Cleaning/lube | Need mobile platform to reach idlers & grease; +30 % labour | All reachable from floor, large service window |

| Extension/re-location | Unhook and lower entire line, fast; new plant must re-check roof load | Must cut anchor bolts, floor holes left; slightly more work |

5. Quick-selection guide

| Application | Recommended mounting |

|---|---|

| 1. Food / electronic clean-room, floor wash-down required | Ceiling + stainless shroud |

| 2. Temporary line, rental workshop, 2–3 year move | Ceiling with quick couplers |

| 3. Heavy load (>50 kg/m), high incline (>15°), high power (>3 kW) | Floor |

| 4. Retrofit of old building with pre-cast hollow core slab | Floor |

| 5. Frequent forklift / AGV traffic under line | Ceiling (clear ≥2.2 m) |

Conclusion

- First check roof load—if insufficient, go floor-mounted.

- “Hanging” is not just saving floor space; it transfers load to the roof and adds extra steps for vibration control, levelling and maintenance access.

- For the same belt width & speed, ceiling suspension costs 15–25 % more, but gives clear floor and flexible layout—ideal for clean rooms, high-changeover lines or mixed traffic areas.

Score the four factors—civil condition, load, budget and maintenance resource—and the choice between “hang” or “stand” becomes straightforward.