Vehicle Paint Appearance Inspection Using Parallel Light Tunnel

The parallel light tunnel is essential equipment for vehicle paint quality inspection, utilizing high-uniformity parallel LED sources (5000K-6500K, Ra≥90) to amplify surface defects like scratches and orange peel through specular reflection. This 6-24m enclosed structure enables comprehensive, consistent detection independent of ambient conditions, significantly reducing subjective judgment errors while ensuring efficient final inspection before vehicle delivery.

Vehicle Paint Appearance Inspection Parallel Light Tunnel

The parallel light tunnel is specialized equipment designed for detecting vehicle body paint quality, widely used in automotive manufacturing paint shops and quality inspection stations.

Working Principle

This equipment utilizes high-brightness, high-uniformity parallel light sources (typically LED or fluorescent lamp arrays) to illuminate the vehicle body surface at specific angles. Since light enters in parallel beams, it maximizes the visibility of subtle paint defects such as scratches, orange peel, pinholes, dirt particles, color mismatch, polishing marks, and paint runs that are difficult to detect with the naked eye.

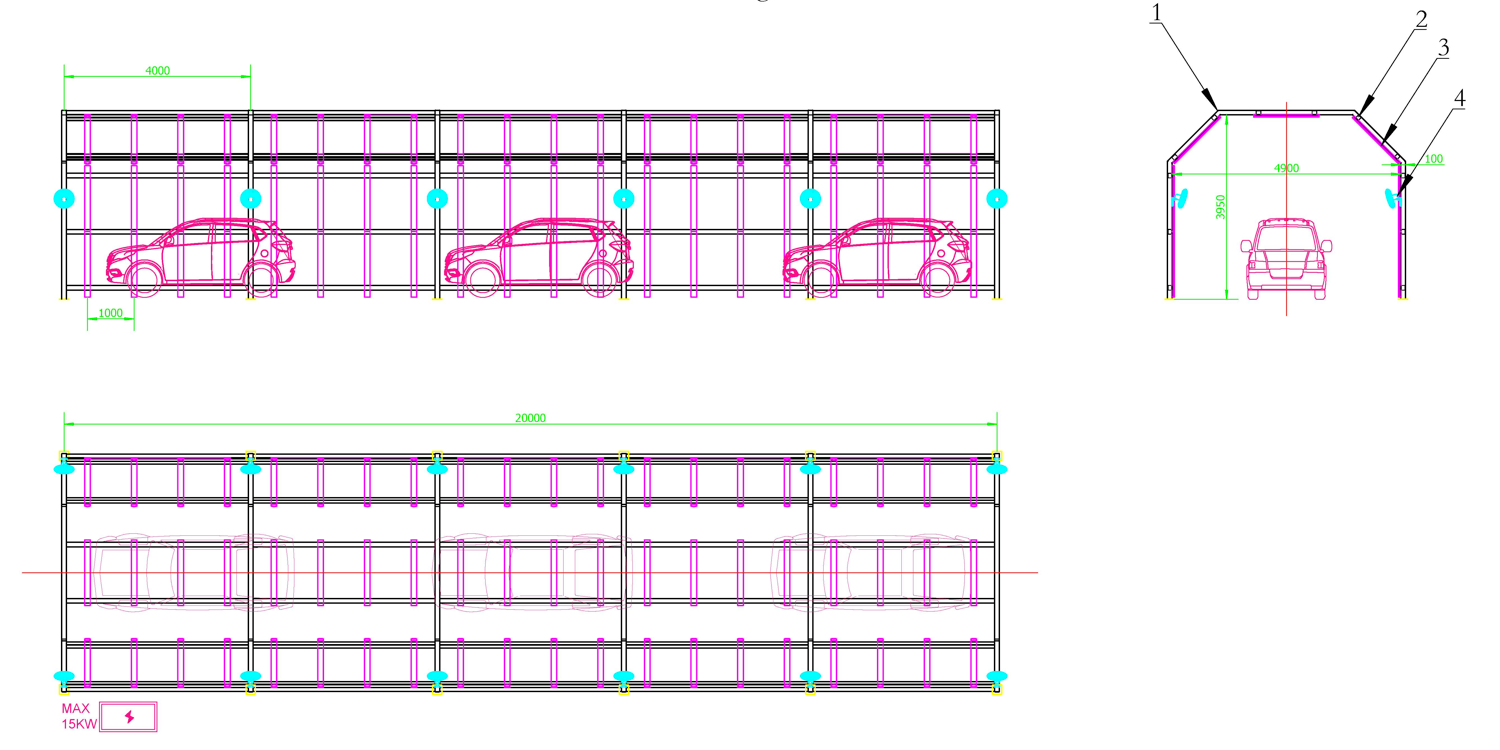

Main Structural Components

- Lighting System: Multiple parallel-arranged LED strips or dedicated fluorescent lamps, with color temperature typically controlled at 5000K-6500K to simulate standard daylight conditions and ensure accurate color judgment

- Tunnel Framework: Enclosed or semi-enclosed corridor constructed with steel structure or aluminum profiles, length generally covering the entire vehicle, height matched to the vehicle body waistline

- Inspection Area: Standard gray scale reference panels installed on the floor, with adjustable brightness fill lights configured on both sides or top of the tunnel

- Conveyor System: Skid or conveyor belt synchronized with the production line, ensuring vehicles pass through the inspection zone at constant speed

- Control System: Intelligent control modules for light intensity adjustment, color temperature switching, and timed on/off operation

Key Technical Parameters

| Parameter Category | Item | Specification | Remarks |

|---|---|---|---|

| Light Source | Type | LED array / T5/T8 fluorescent | LED is current mainstream solution |

| Color Temperature | 5000K ~ 6500K | Standard D65 source or adjustable | |

| Color Rendering Index (Ra) | ≥90 | Ensures authentic color reproduction | |

| Illuminance | 800 ~ 1500 lux | Uniform distribution from entrance to exit | |

| Light Parallelism | ≤2° divergence angle | Critical parameter affecting defect detection rate | |

| Flicker | ≤5% | Prevents visual fatigue and misjudgment | |

| Tunnel Structure | Length | 12m ~ 24m | Customized based on vehicle model and takt time |

| Width | 3.5m ~ 5m | Provides space for side inspection | |

| Height | 2.8m ~ 3.5m | Covers roof and high-roof vehicle models | |

| Frame Material | Carbon steel with powder coating / Aluminum alloy | Rust-resistant, easy to clean | |

| Installation | Mounting | Foundation fixed / Ceiling suspended | Selected based on workshop conditions |

| Ambient Illuminance | ≤50 lux (external interference) | Tunnel exterior requires light shielding | |

| Floor Requirement | Standard gray panel (N5~N7) | For color difference comparison | |

| Operation | Passage Speed | 3 ~ 8 m/min | Matched to production line takt time |

| Inspection Time | 60s ~ 120s/unit | Includes roof and side inspection | |

| Operating Temperature | 10°C ~ 40°C | Standard paint shop environment | |

| Electrical | Input Voltage | AC 380V / 220V ±10% | Three-phase or single-phase optional |

| Total Power | 8kW ~ 25kW | Depends on tunnel length and lamp density | |

| Protection Rating | IP54 | Dust and splash water resistant | |

| Control Functions | Dimming Range | 10% ~ 100% stepless adjustment | Adaptable to different paint colors |

| Color Temperature Switching | 3000K / 4000K / 6500K | Multiple options (premium configuration) | |

| Smart Interface | RS485 / Ethernet | Integration with workshop MES system |

Technical Advantages

Compared with traditional point light sources or natural light inspection, the parallel light tunnel offers the following characteristics:

- Defect Amplification Effect: Parallel light creates specular reflection that forms obvious light-dark contrast for minute irregularities

- High Consistency: Unaffected by external weather or time of day, maintaining constant inspection conditions 24/7

- High Efficiency: Complete vehicle coverage achieved in a single pass

- Reduced Subjective Error: Standardized lighting environment minimizes judgment variations among different inspectors

Application Scenarios

Primarily used for final inspection stations (Final Inspection) after passenger vehicle and commercial vehicle painting completion, this is critical equipment for paint quality control before vehicle delivery. It is also commonly used for quality verification of reworked vehicles at 4S dealership after-sales service centers.